Embossed Thermal Lamination Film for Inkjet Printing

- Product name: Embossed thermal lamination film for inkjet printing

- Adhesive: EVA

- Thickness: 38mic

- Width: 300mm~1890mm

- Length: 200m~4000m

- Core: 1 inch(25.4mm)/3 inch(76.2mm)

- Overview

- Specification

- Advantages

- End-To-End Customer Support

- After-sales Service

- Recommended Products

Product description:

The main difference between the embossed thermal lamination film for inkjet printing and the embossable one is that the embossed thermal lamination film for inkjet printing has completed the embossing process during production. After lamination, the self embossing process can be omitted, which is suitable for small batch lamination requirements.

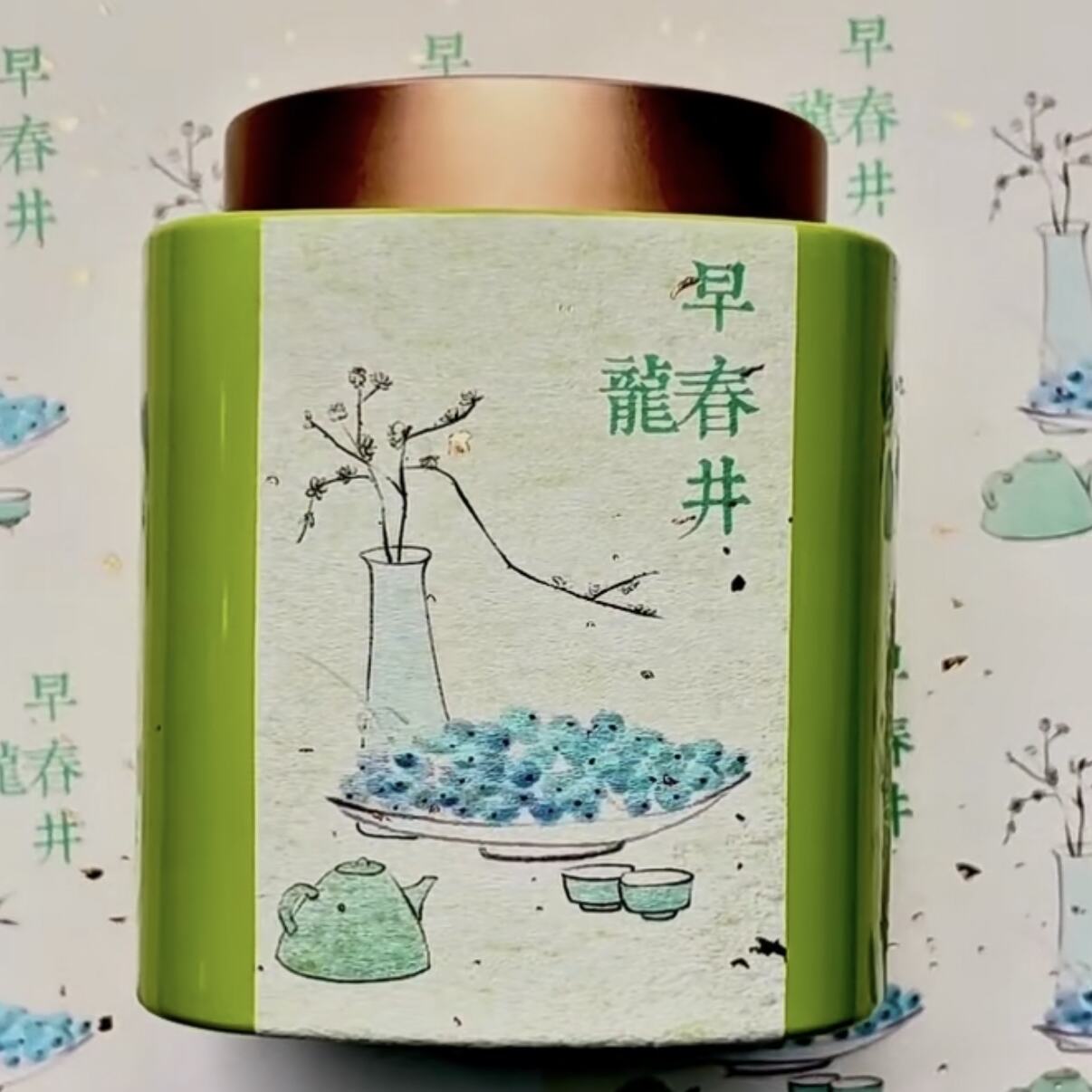

Project Showcase:

TicketLabel Hangtag Greeting Card

Gift BoxCalenderBrochureBox

Specification:

|

Product name |

Embossed thermal lamination film for inkjet printing |

|

Adhesive |

EVA |

|

Surface |

|

|

Thickness |

38mic |

|

Width |

300mm~1890mm |

|

Length |

200m~4000m |

|

Core |

1 inch(25.4mm)/3 inch(76.2mm) |

|

Packaging |

Top and bottom box/Carton box |

|

Laminating temp. |

110℃~120℃ |

|

Place of origin |

Guangdong, China |

Advantages:

- Time and Cost Efficiency for Small Batches:

Since the embossing process is already completed during production, it significantly reduces the time and labor required for small batch lamination projects. There is no need to set up and operate an embossing machine separately, which can be time-consuming and may require additional equipment and operator skills. This leads to cost savings in terms of both production time and the potential investment in embossing equipment and its maintenance.

- Consistent Embossing Quality:

The embossed pattern on the film is produced under controlled manufacturing conditions. This ensures a high level of consistency in the embossing quality. Each laminated piece will have the same precise and uniform embossed design, enhancing the overall appearance and professionalism of the printed materials.

- Versatility in Application:

Besides its prime application in the digital advertising industry, it can be widely used in the field of food flexible packaging lamination.

End-To-End Customer Support:

Customized Film Solutions:

Solve Your Specific Pain Points

Edge warping of heat-intolerant printing materials after laminating

SOLUTION:LowTemperature Thermal Lamination Film

Delamination of digital toner printings after laminating

SOLUTION:Digital Thermal Lamination Film

Low adhesive of inkjet printings after laminating

SOLUTION:Thermal Lamination Film for Inkjet Printing

Solution:

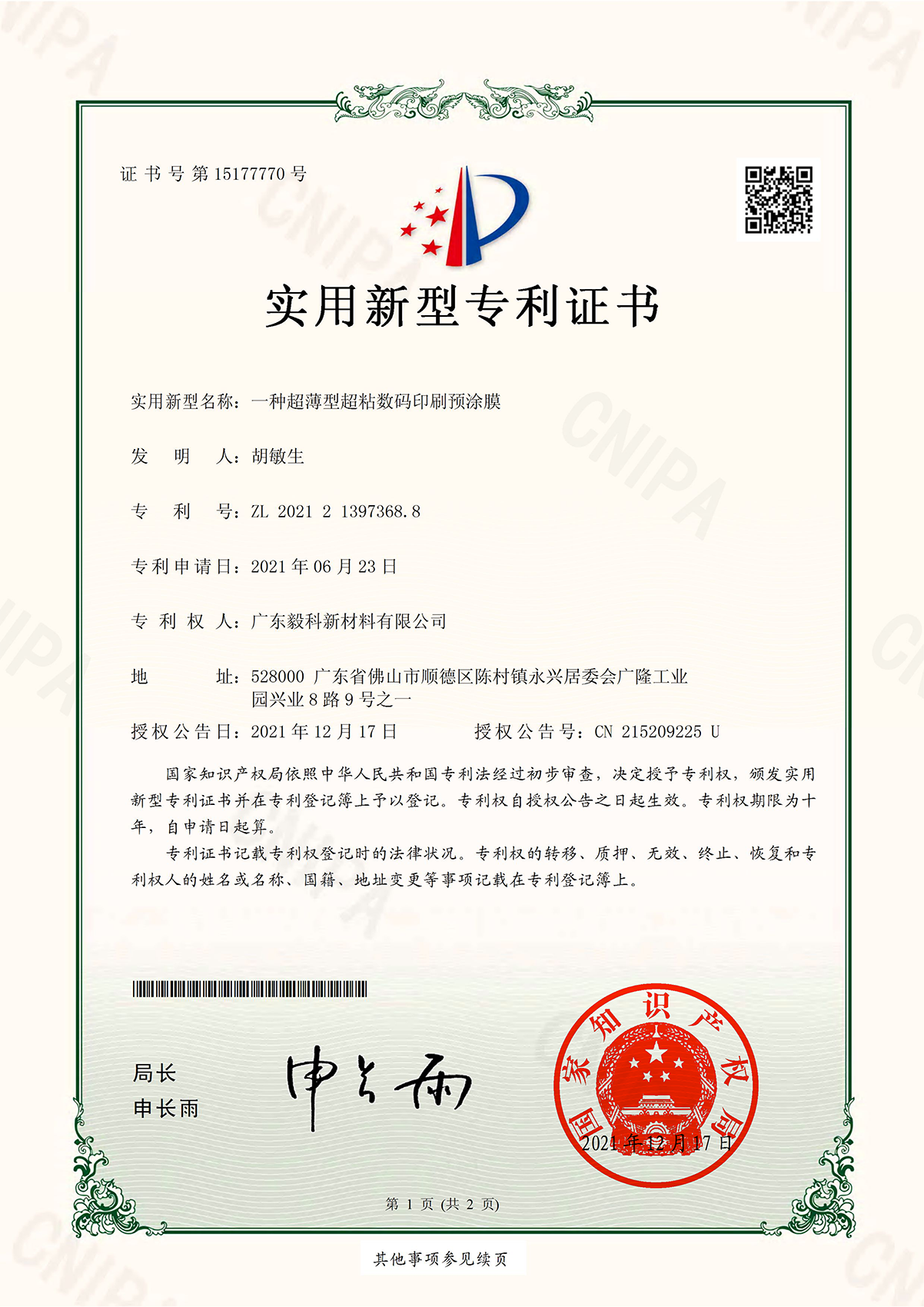

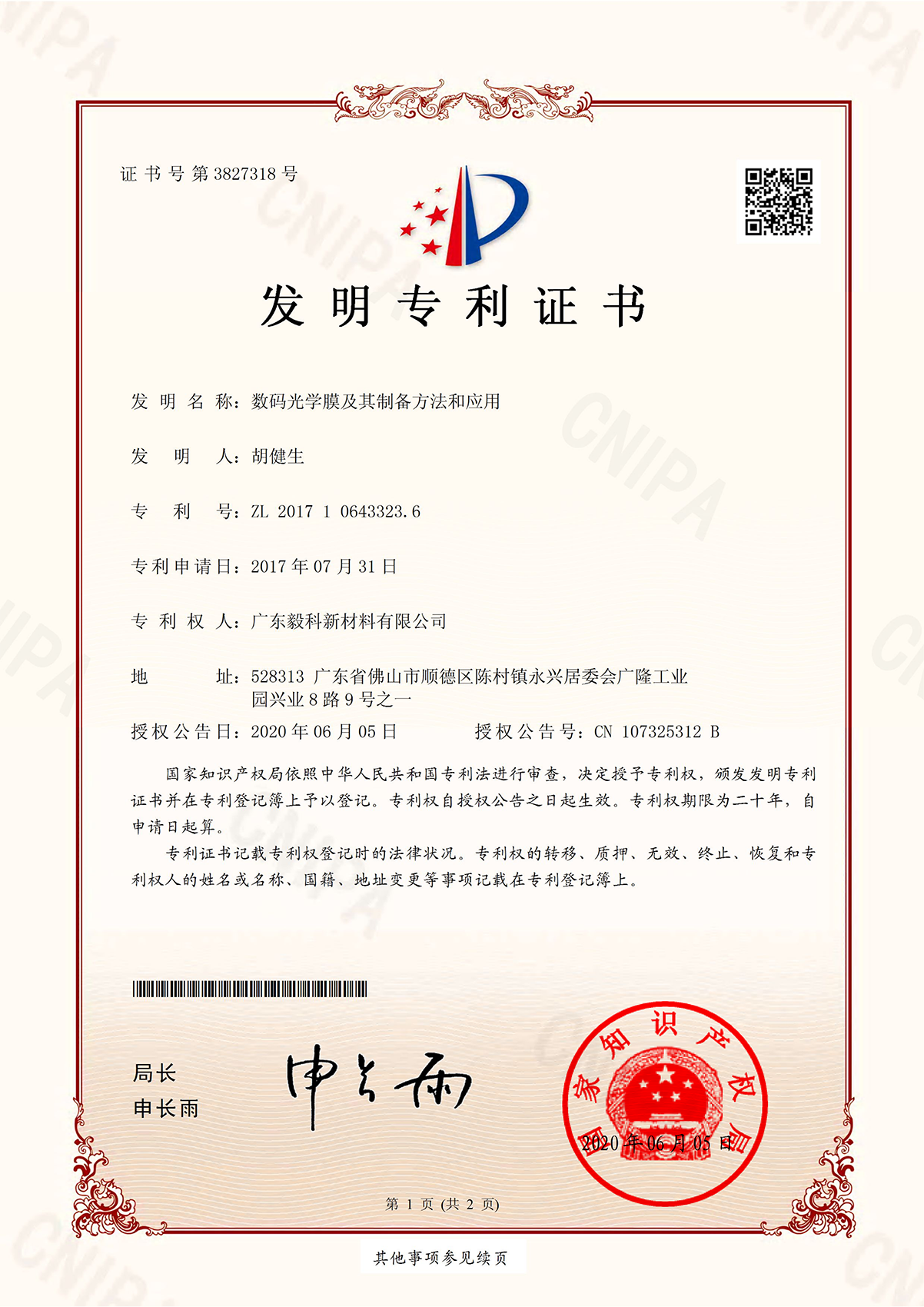

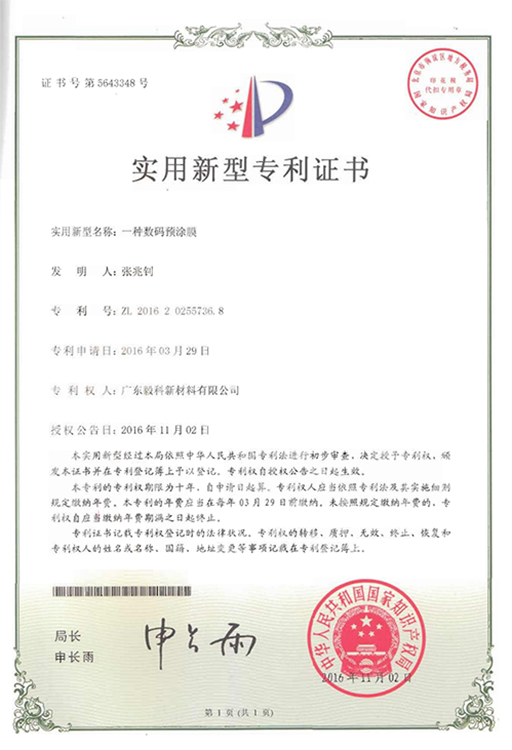

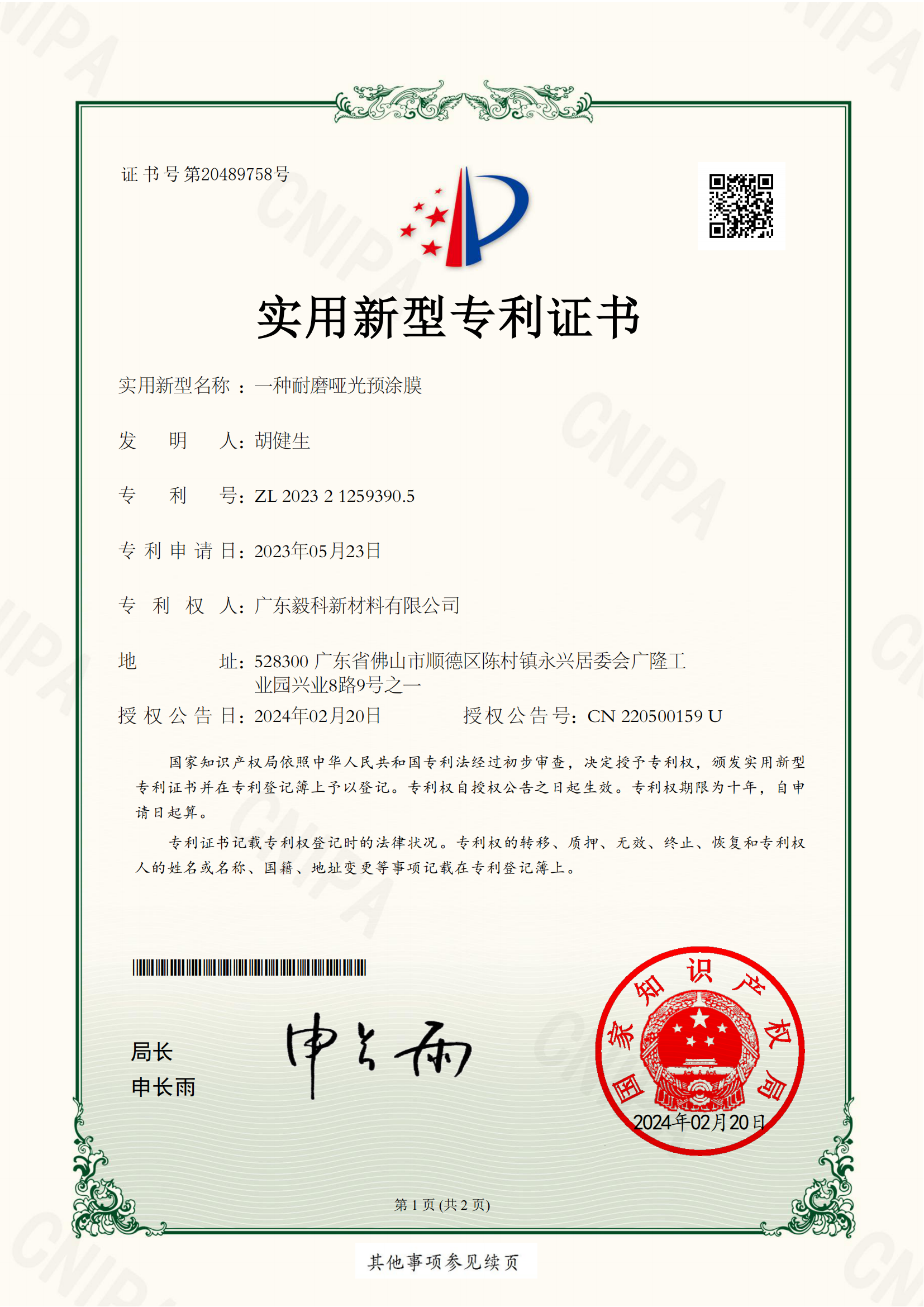

Deep Cooperation with School's Research Department Delivering Customized Solution

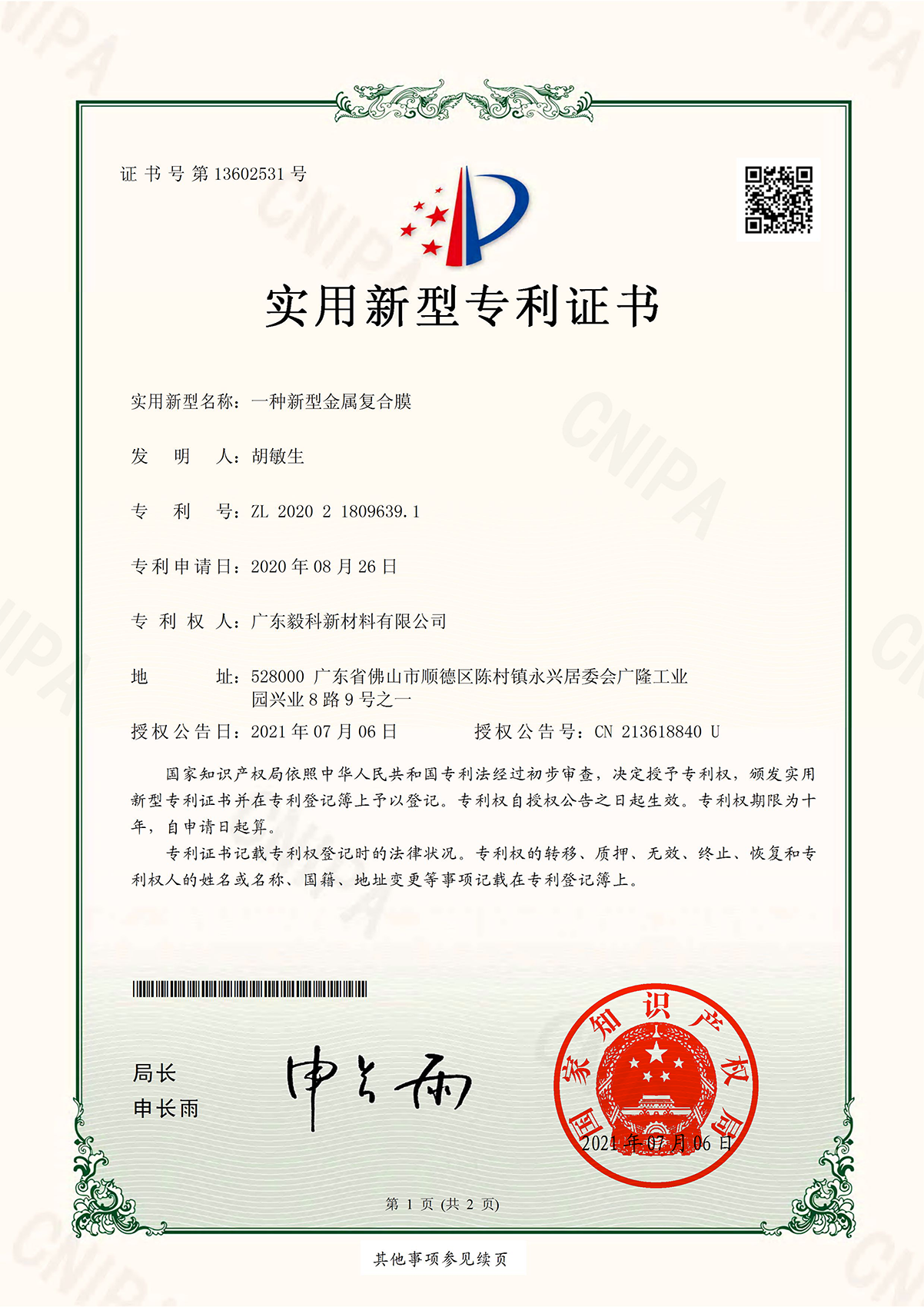

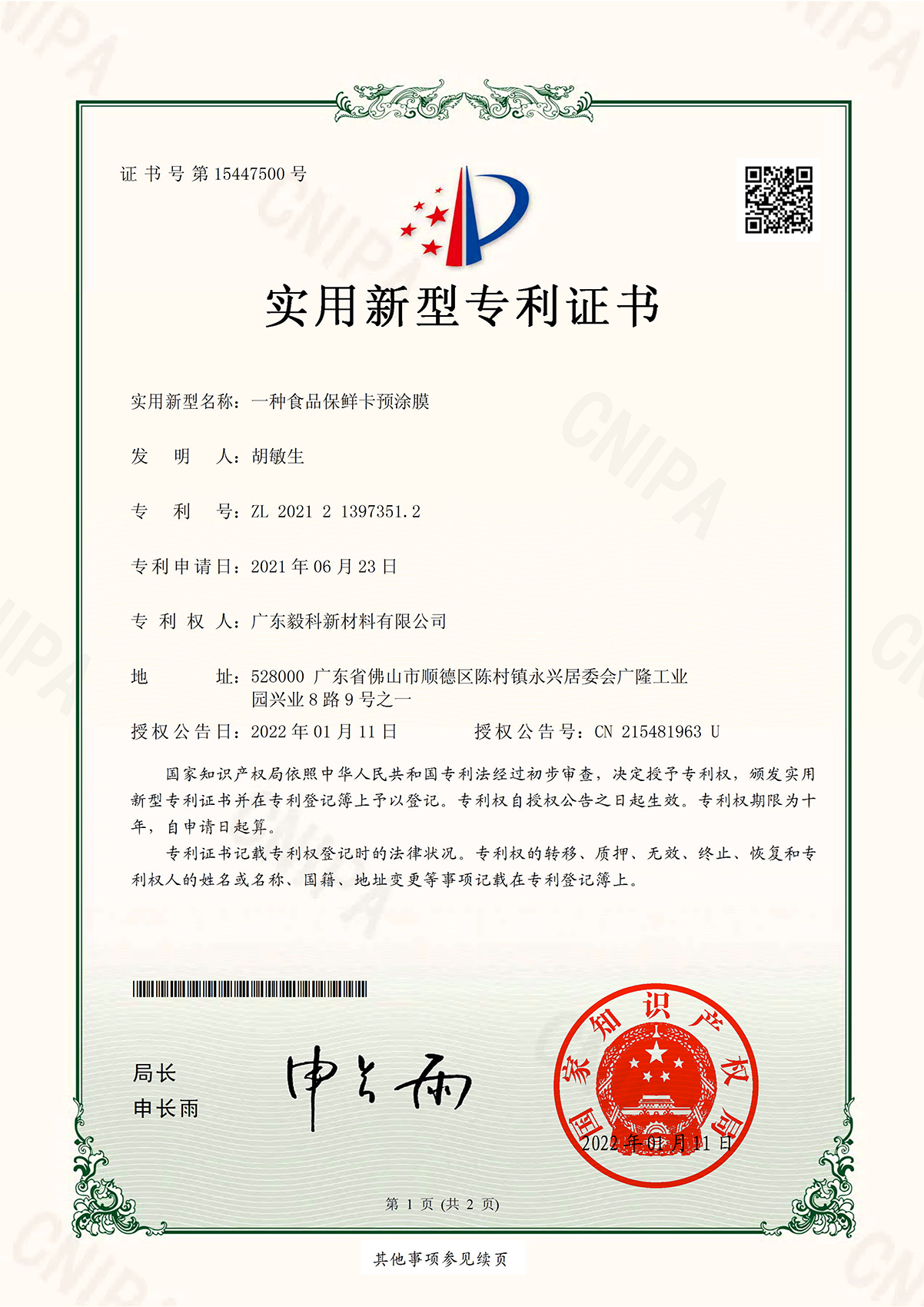

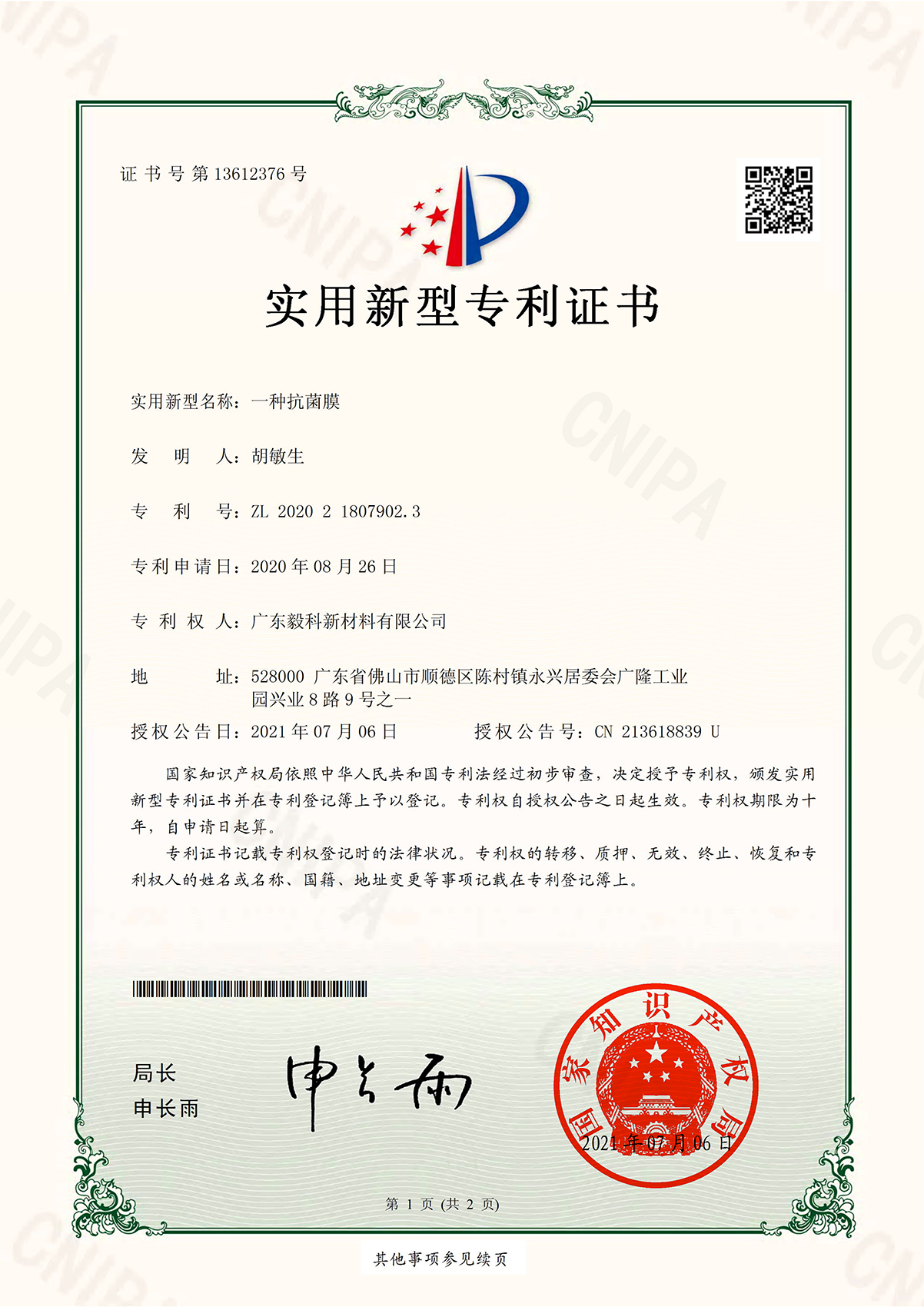

Compliance:

RoHS & REACH & Food Contact Material Triple-Certified

Packaging & Shipping:

FAQ:

Q1:Are you a factory or a trading company?

A: We are a company integrating R&D, production and sales.

Q2: How do you ensure the quality of your products?

A: We do end-to-end quality control-real time thickness check, corona value detection, bond strength testing, performance packaging.

Q3: What is your main products?

A: EKO has a broad product portfolio by catering to a wide range of industry needs, including BOPP thermal lamination film, digital super sticky thermal lamination film, thermal lamination film for inkjet printing, digital toner foil, DTF film & paper, heat sealable film, etc..

Q4: Can I get some samples or trial order for trying?

A: Yes, we provide free samples, the sample size is 320mm*30m per roll. You only need to pay for the shipping cost.

Q5: What services can we get?

A: We provide end-to-end customer support including professional customer service, customized solution, free samples, trial order, product information pack, technical consulting, full logistics tracking and feedback, comprehensive customer complaint process.

Q6: What payment terms do you offer?

A: We offer EXW, FOB, CIF, DAP, DDP, etc..