Anti-Scratch Thermal Lamination Film

- Product name: Anti-scratch thermal lamination film

- Adhesive: EVA

- Surface: Matt

- Thickness: 30mic

- Width: 300mm~1890mm

- Length: 200m~4000m

- Overview

- Specification

- Advantages

- End-To-End Customer Support

- After-sales Service

- Recommended Products

Product description:

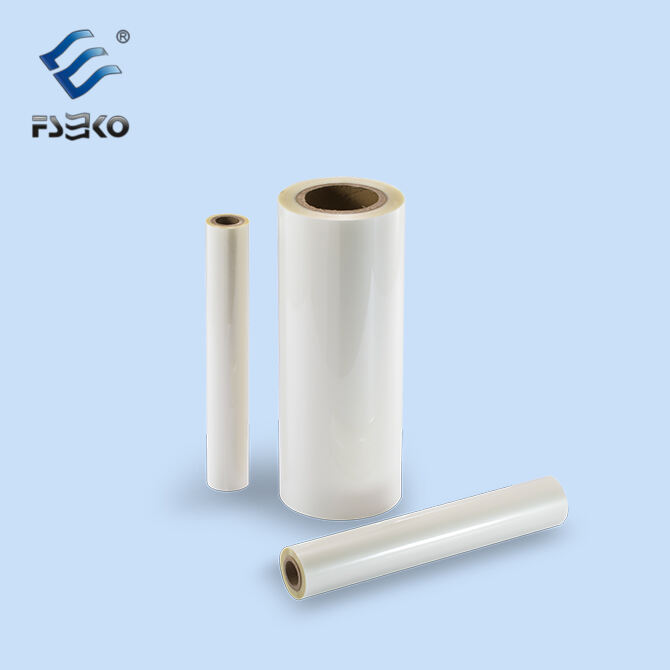

Anti-scratch thermal lamination film is a specialized type of lamination film designed to provide protection against scratches and abrasions.

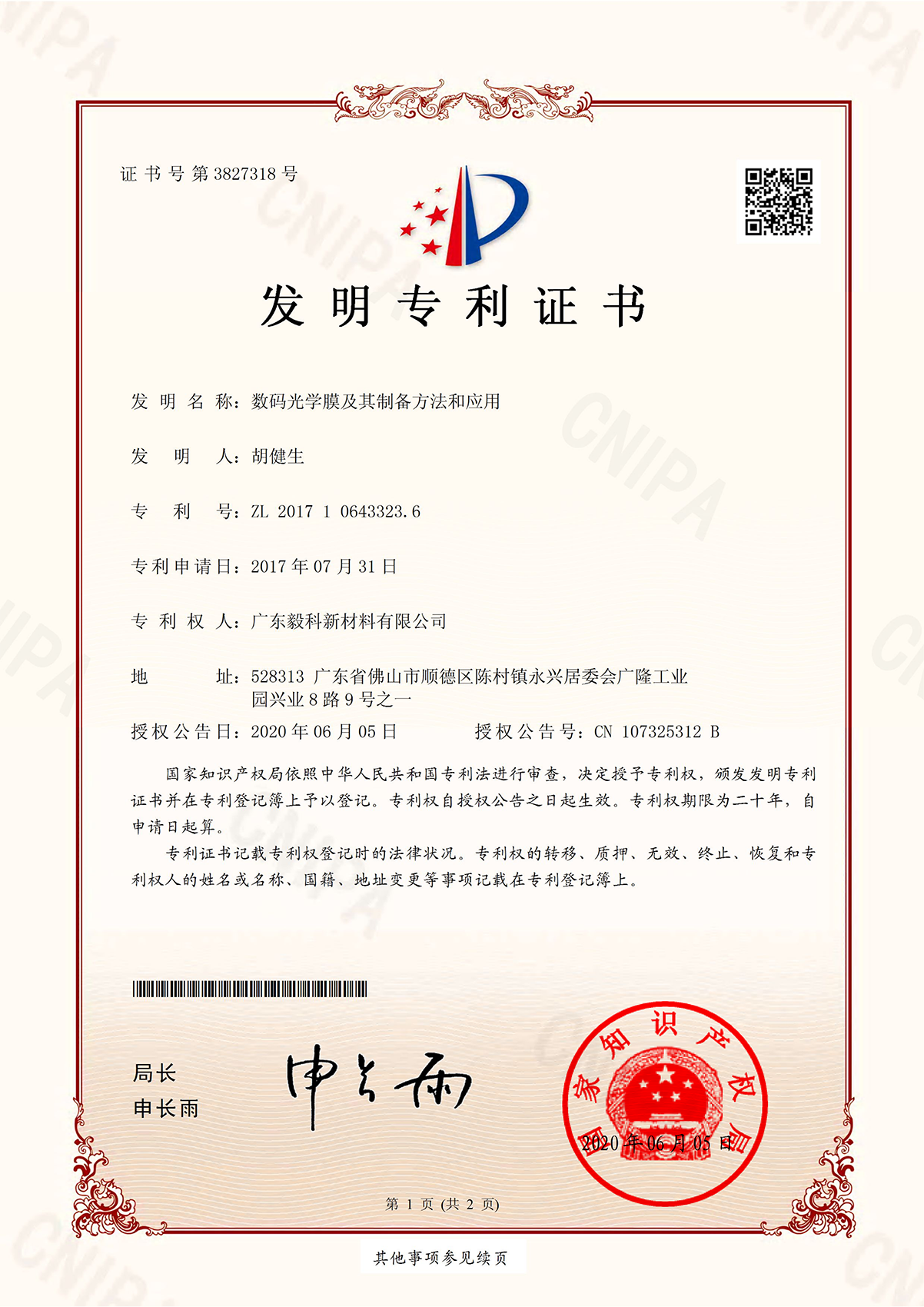

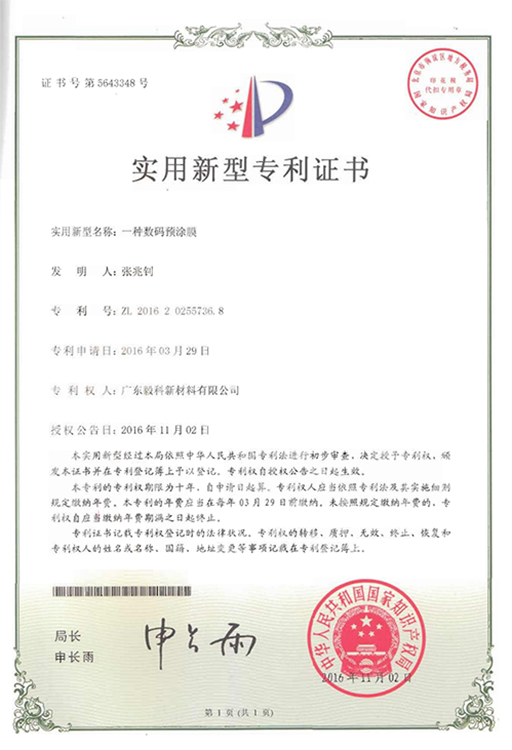

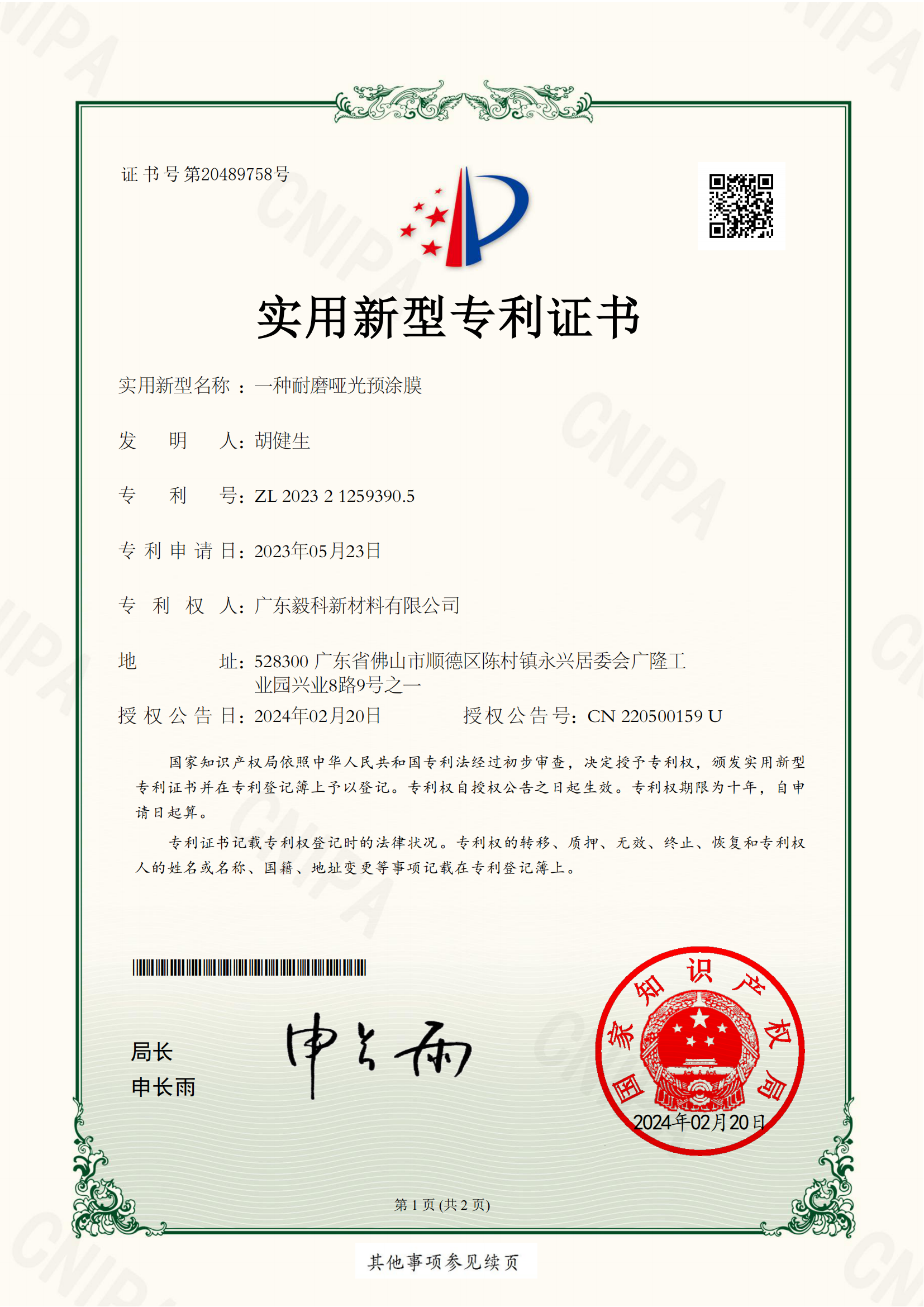

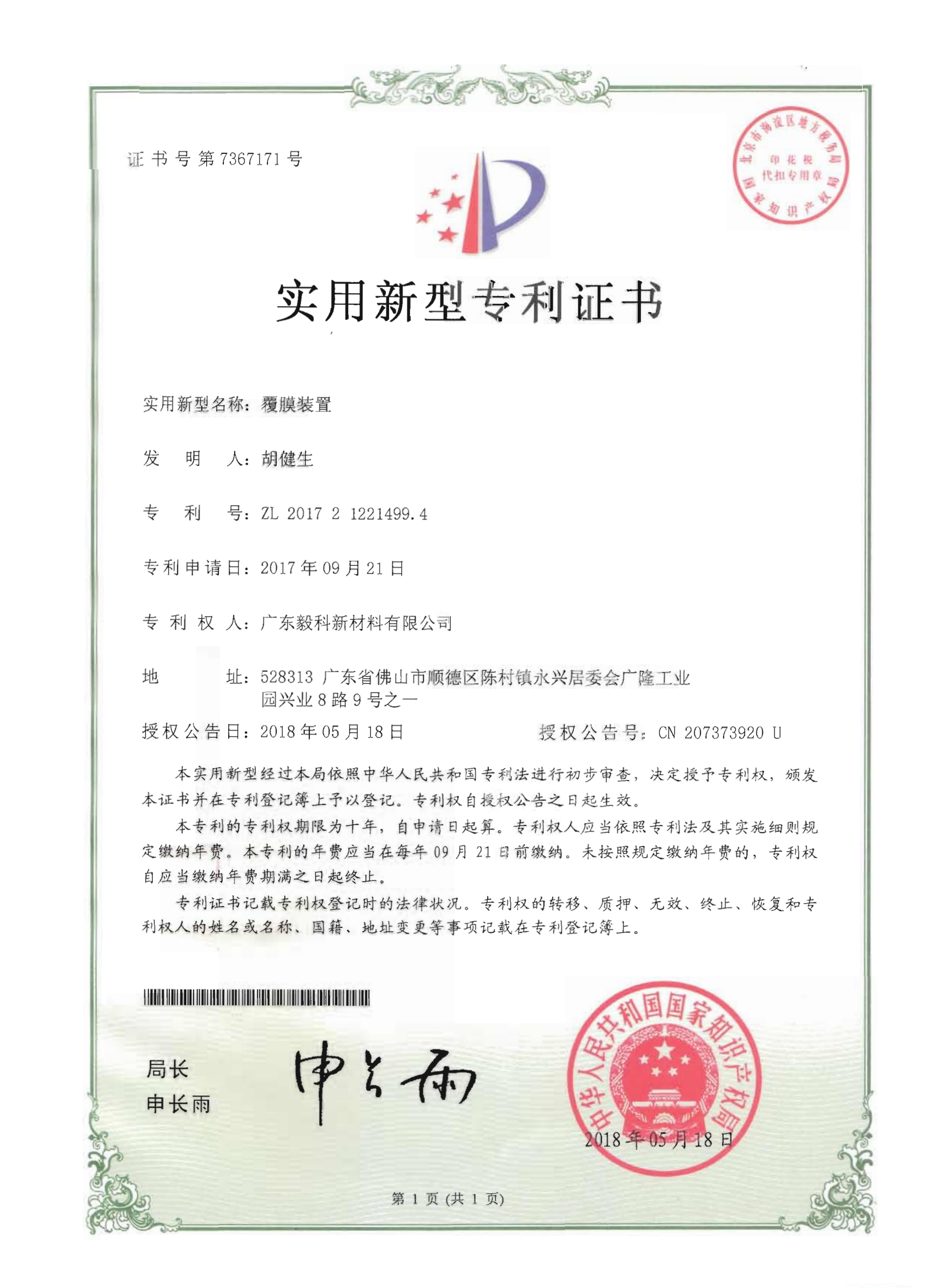

EKO’s anti-scratch thermal lamination film consists of BOPP film and EVA glue. If for digital printings, digital anti-scratch thermal lamination film is much more suitable. Modified formula, super strong adhesive but without thickening the EVA layer.

Project Showcase:

TicketLabel Hangtag Greeting Card

Gift BoxCalenderBrochureBox

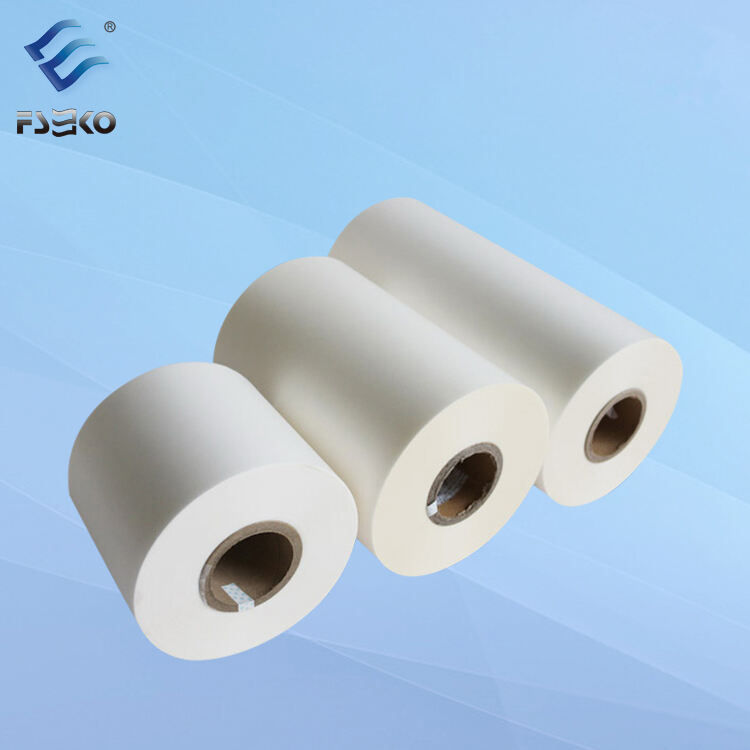

Specification:

|

Product name |

Anti-scratch thermal lamination film |

|

Adhesive |

EVA |

|

Surface |

Matt |

|

Thickness |

30mic |

|

Width |

300mm~1890mm |

|

Length |

200m~4000m |

|

Core |

1 inch(25.4mm)/3 inch(76.2mm) |

|

Packaging |

Top and bottom box/Carton box |

|

Laminating temp. |

105℃~120℃ |

|

Place of Origin |

Guangdong, China |

Advantages:

- Superior Scratch Resistance:

It provides a highly effective barrier against scratches, maintaining the aesthetic appeal of the laminated product. This is beneficial for products where appearance matters, such as luxury goods packaging, display panels, and ID cards.

- Durability and Long-Term Protection:

Anti-scratch thermal lamination film is designed to be durable and withstand various environmental conditions. And it provides long-term scratch protection, which is cost-effective in the long run.

- Versatility in Applications:

It can be used in a wide range of industries and applications. In the packaging industry, it is used to protect consumer goods such as cosmetics, electronics, and food products from scratches during transportation and storage. In the printing and graphic arts field, it enhances the durability of printed materials and adds a professional touch to the final product.

End-To-End Customer Support:

Customized Film Solutions:

Solve Your Specific Pain Points

Edge warping of heat-intolerant printing materials after laminating

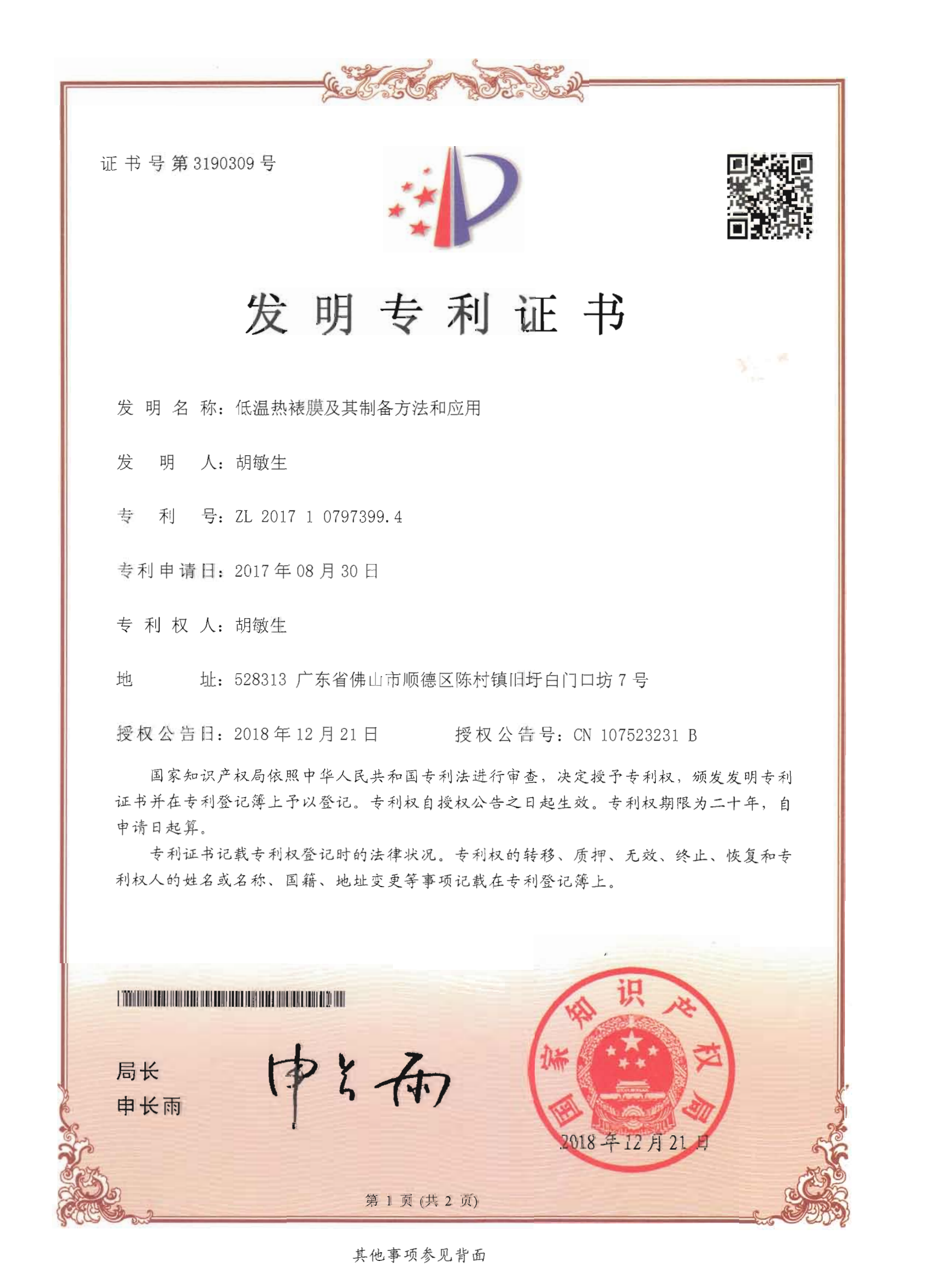

SOLUTION:LowTemperature Thermal Lamination Film

Delamination of digital toner printings after laminating

SOLUTION:Digital Thermal Lamination Film

Low adhesive of inkjet printings after laminating

SOLUTION:Thermal Lamination Film for Inkjet Printing

Solution:

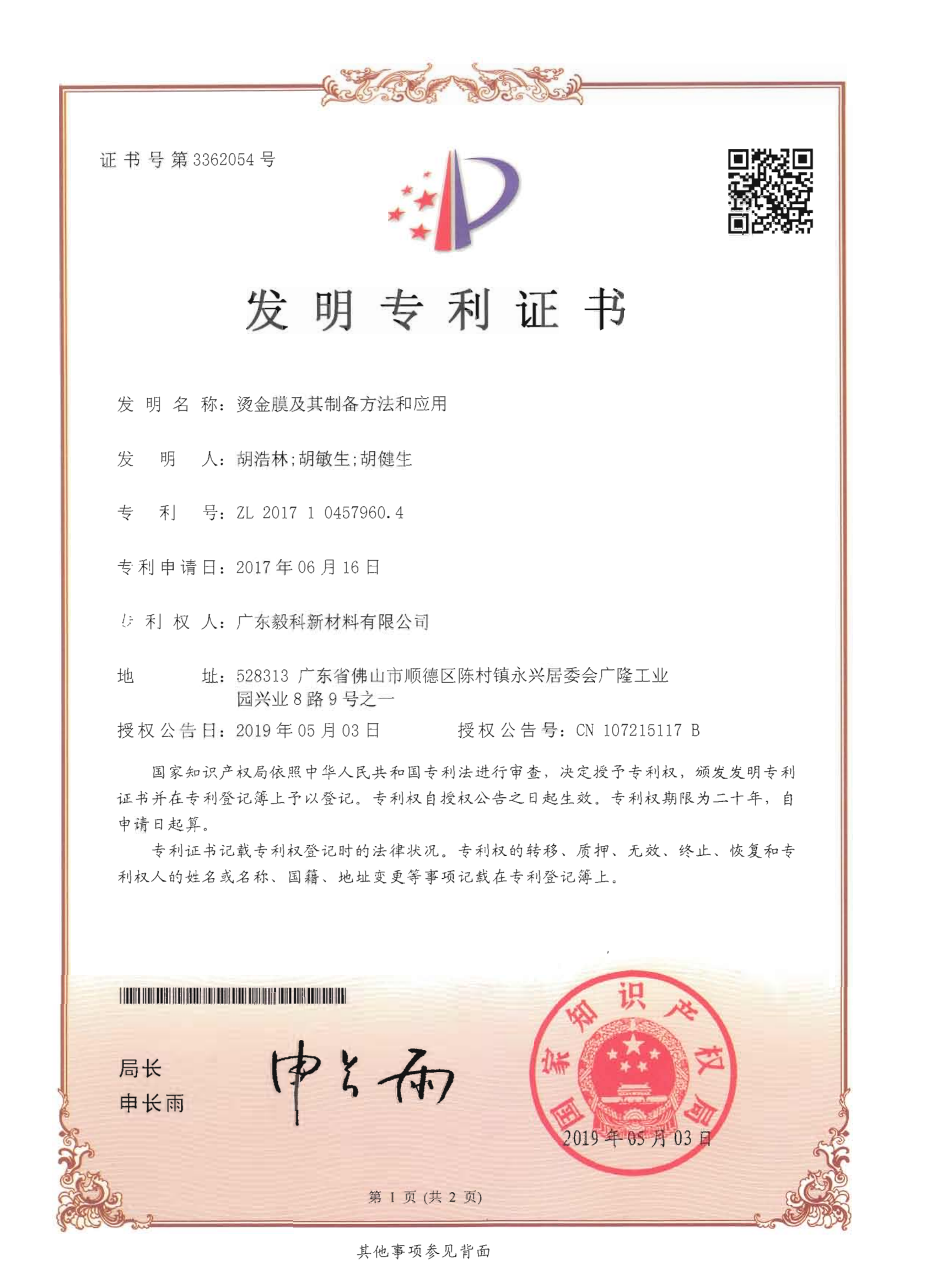

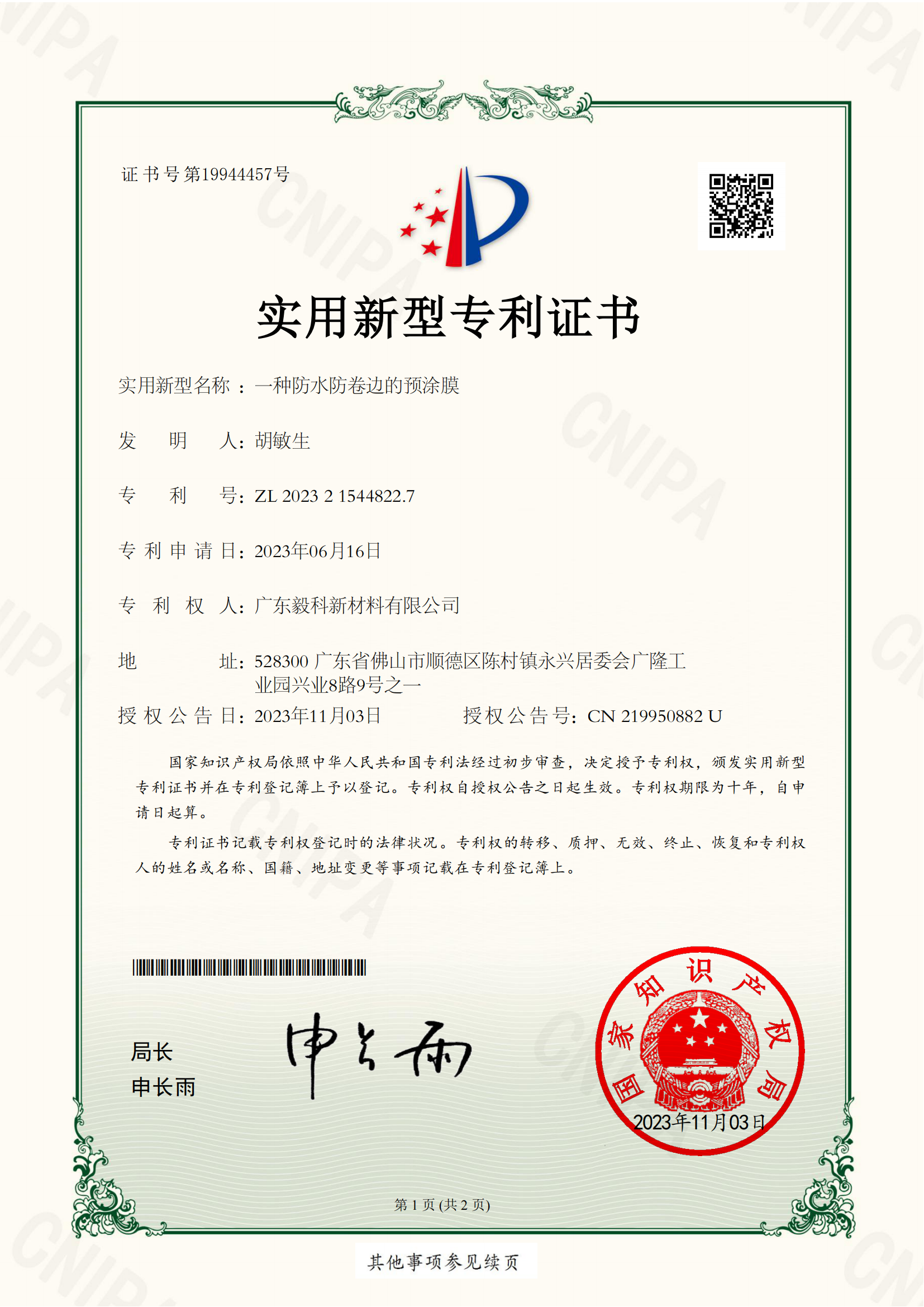

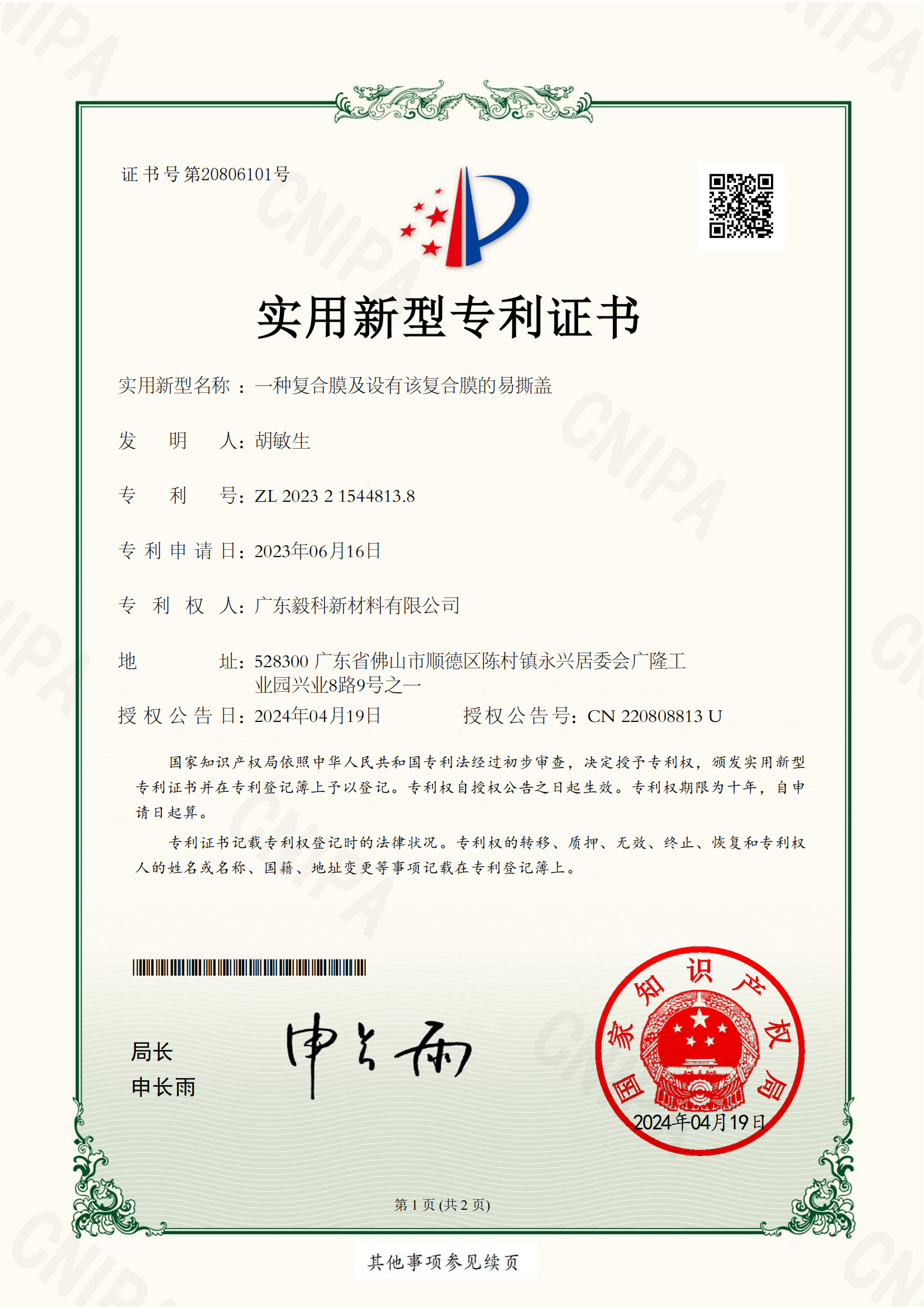

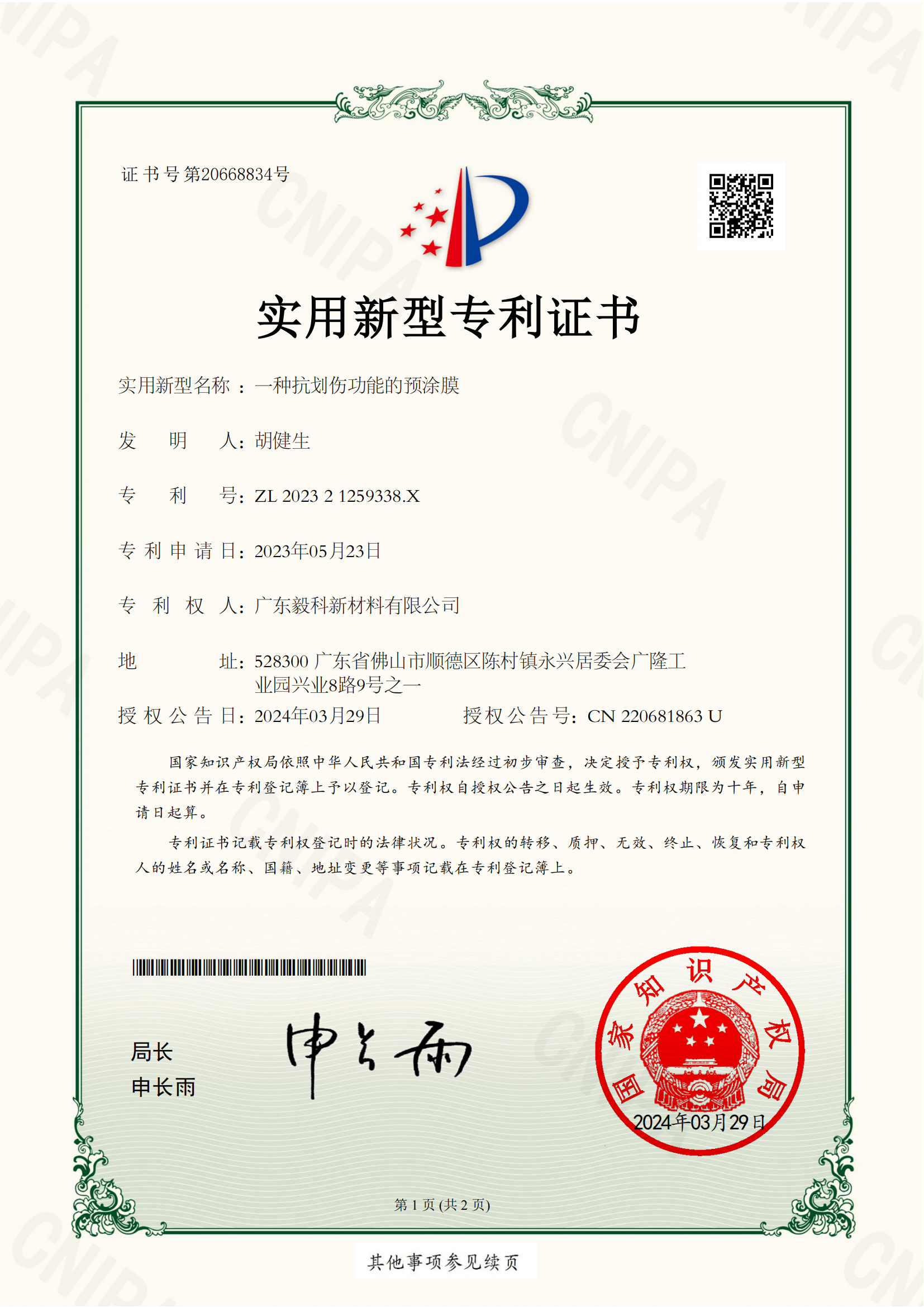

Deep Cooperation with School's Research Department Delivering Customized Solution

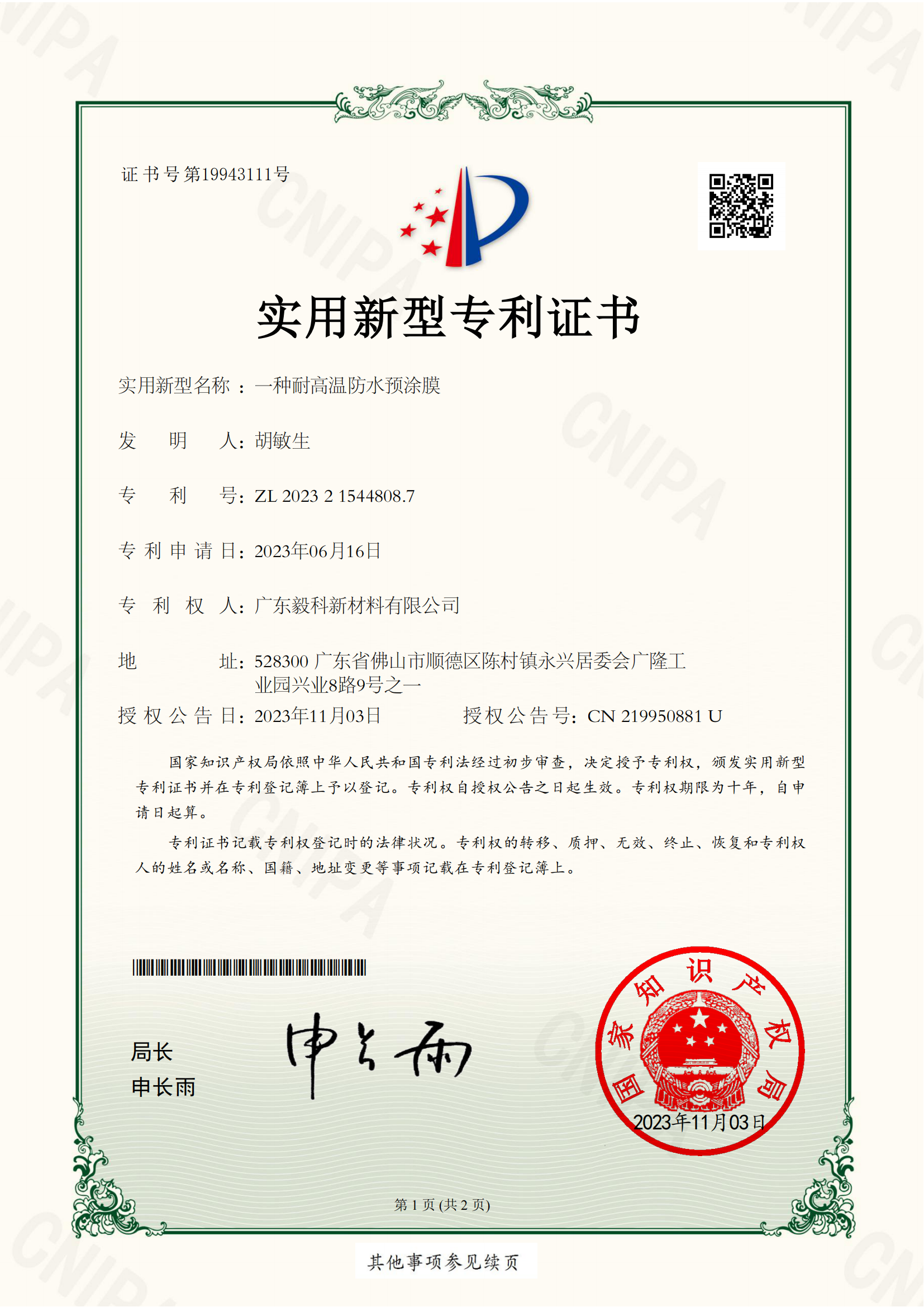

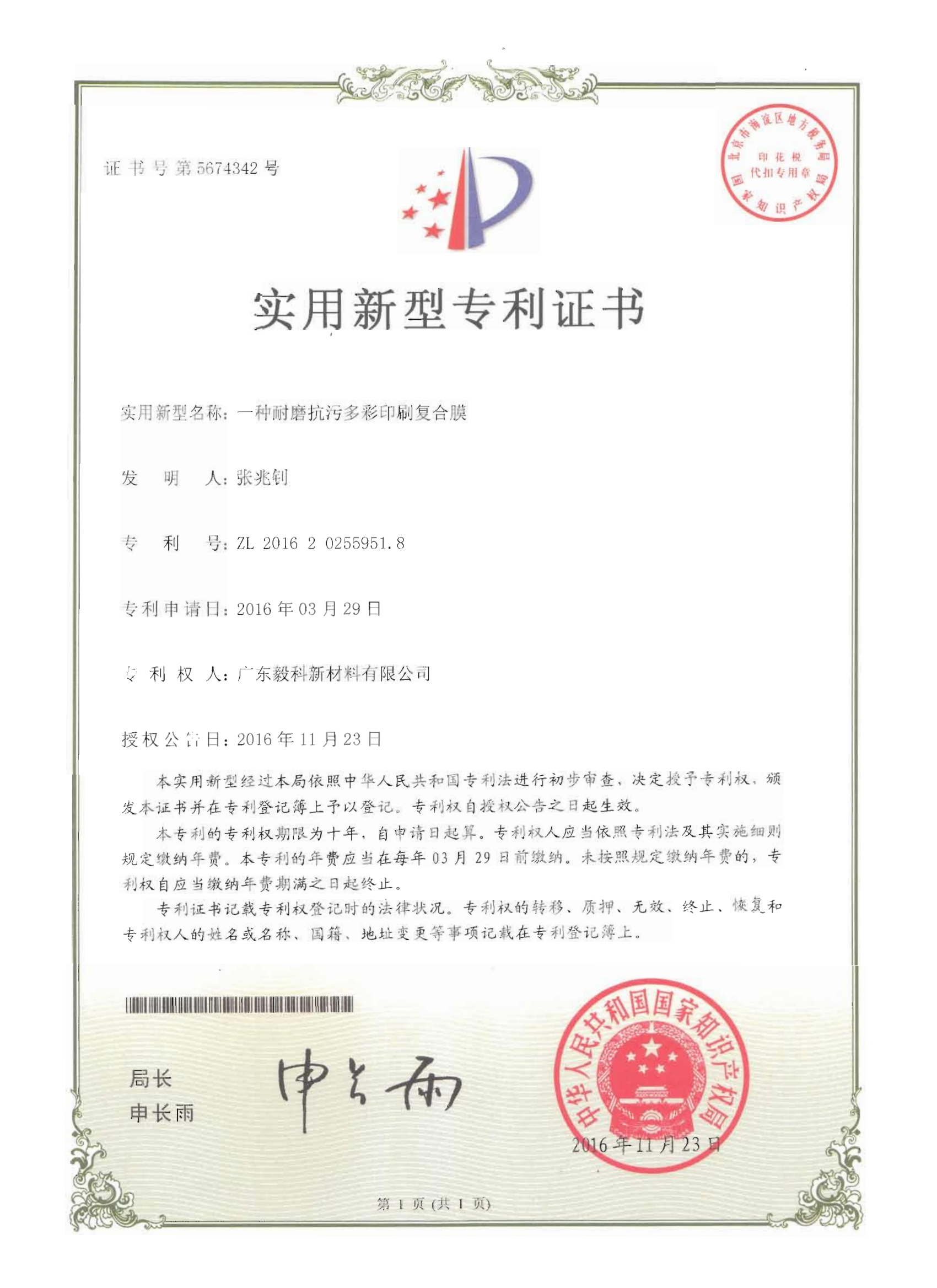

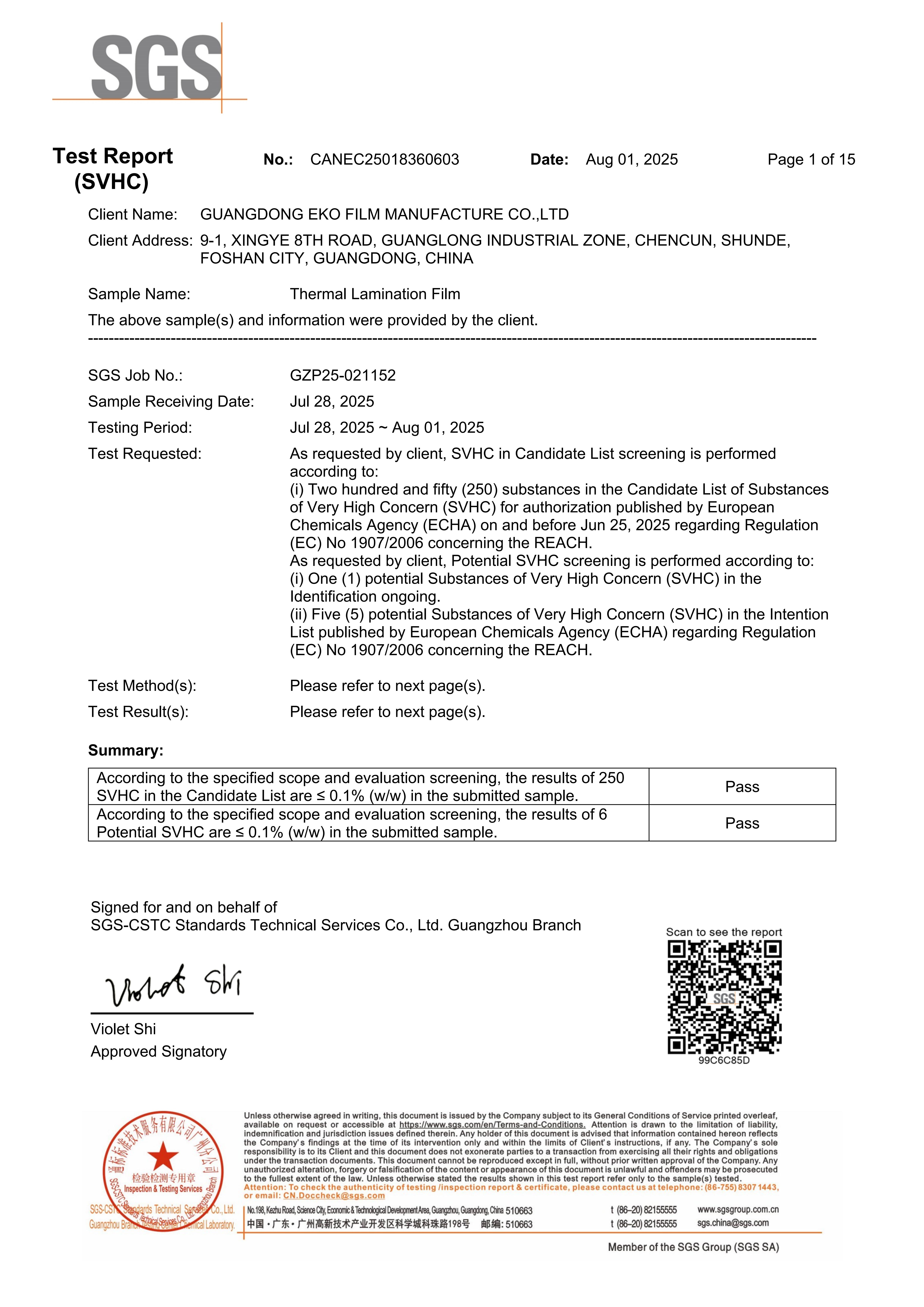

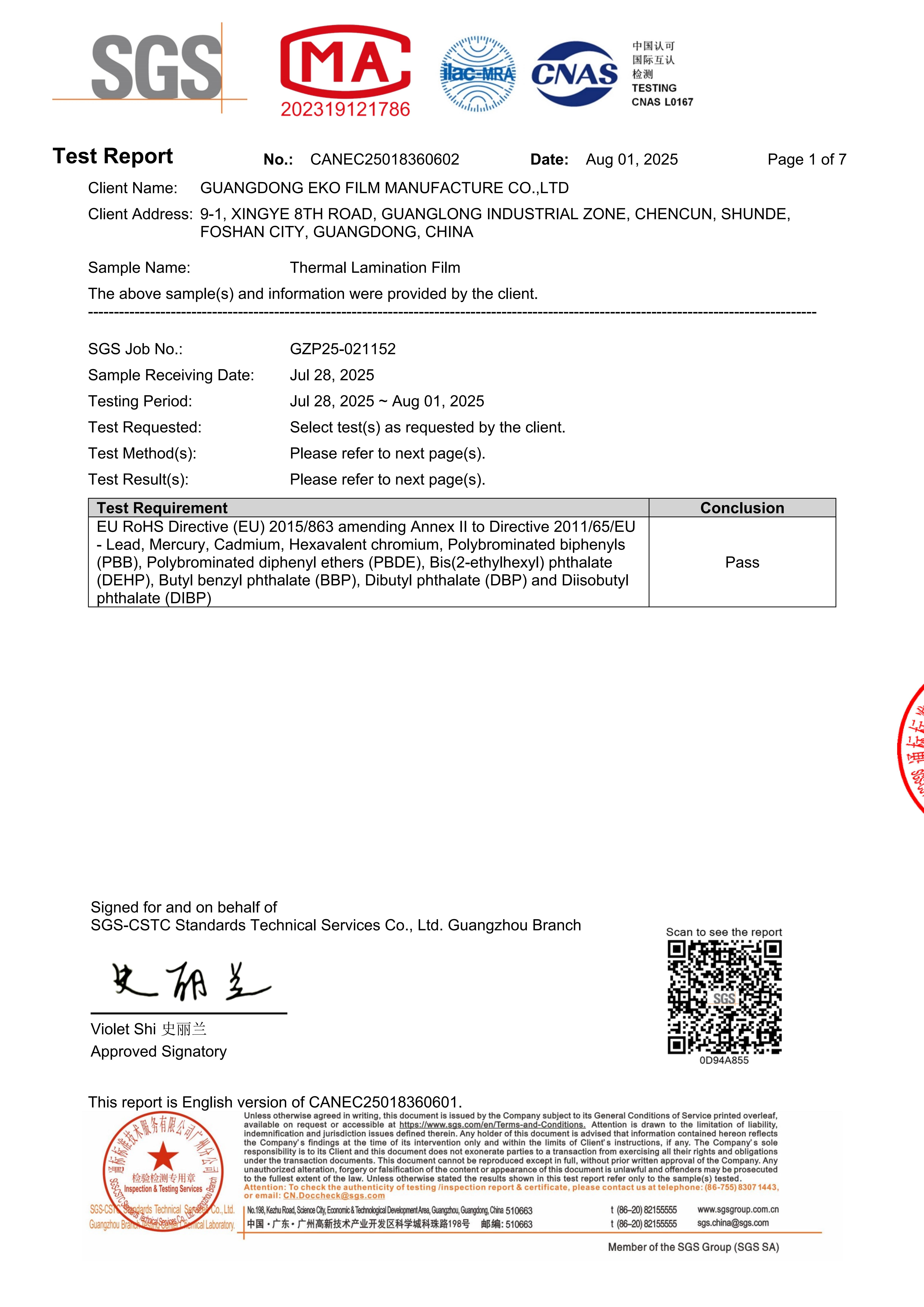

Compliance:

RoHS & REACH & Food Contact Material Triple-Certified

Packaging & Shipping:

FAQ:

Q1:Are you a factory or a trading company?

A: We are a company integrating R&D, production and sales.

Q2: How do you ensure the quality of your products?

A: We do end-to-end quality control-real time thickness check, corona value detection, bond strength testing, performance packaging.

Q3: What is your main products?

A: EKO has a broad product portfolio by catering to a wide range of industry needs, including BOPP thermal lamination film, digital super sticky thermal lamination film, thermal lamination film for inkjet printing, digital toner foil, DTF film & paper, heat sealable film, etc..

Q4: Can I get some samples or trial order for trying?

A: Yes, we provide free samples, the sample size is 320mm*30m per roll. You only need to pay for the shipping cost.

Q5: What services can we get?

A: We provide end-to-end customer support including professional customer service, customized solution, free samples, trial order, product information pack, technical consulting, full logistics tracking and feedback, comprehensive customer complaint process.

Q6: What payment terms do you offer?

A: We offer EXW, FOB, CIF, DAP, DDP, etc..