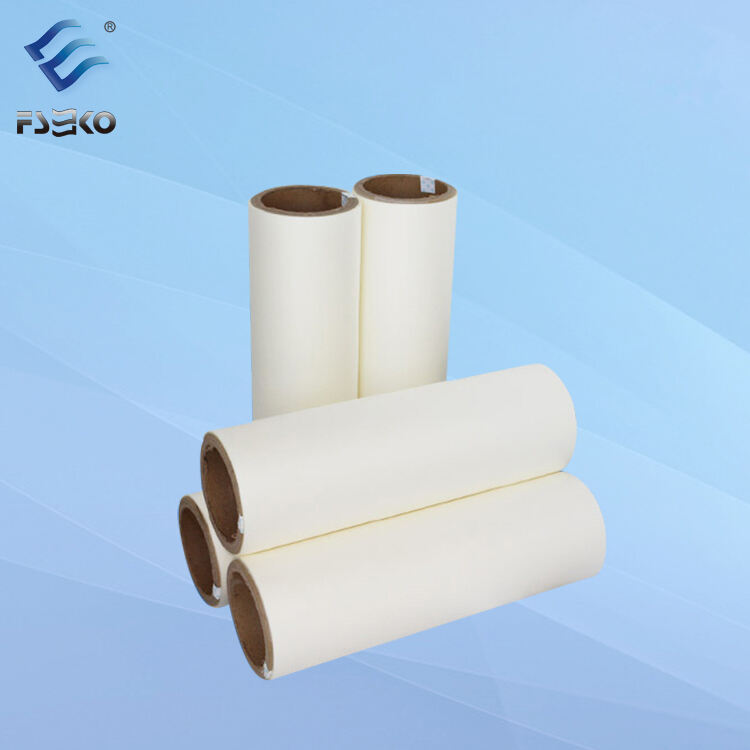

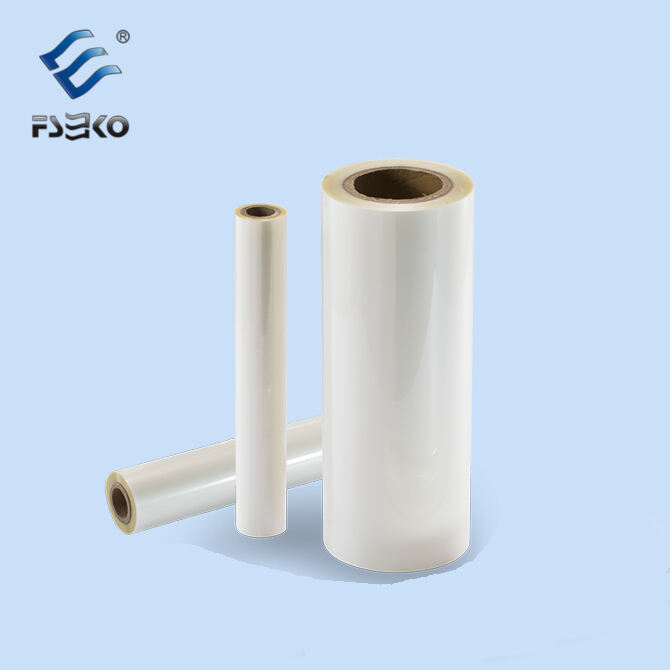

DTF Paper

- Product name: DTF paper

- Gram weight: 70g/㎡

- Width: 330mm, 600mm, customized

- Length: 100m, 200m, customized

- Laminating temp.: 160℃

- Laminating time: 5~8 seconds

- Place of origin: Guangdong, China

- Overview

- Specification

- Advantages

- End-To-End Customer Support

- After-sales Service

- Recommended Products

Product description:

Both DTF paper and DTF film are used in the field of digital transfer printing. However, DTF paper is a plastic-free and environmentally-friendly option. There is no need to replace the DTF printing equipment when using it, and its ink absorption property is as excellent as that of DTF film. In today's era with an emphasis on environmental protection, the recyclability of DTF paper makes it a more sustainable choice and can contribute to the development of green printing and environmental protection industries.

Specification:

|

Product name |

DTF paper |

|

Gram weight |

70g/㎡ |

|

Width |

330mm, 600mm, customized |

|

Length |

100m, 200m, customized |

|

Laminating temp. |

160℃ |

|

Laminating time |

5~8 seconds |

|

Place of origin |

Guangdong, China |

Advantages:

- Affordable and Cost-Effective:

Introducing the DTF paper as a new printing material to address the issue of high supply costs for our customers. As a result, it is significantly more economical compared to traditional DTF film. If you’re aiming for substantial profits in the digital printing industry without requiring large initial investments, consider EKO DTF paper as a long-term supply solution.

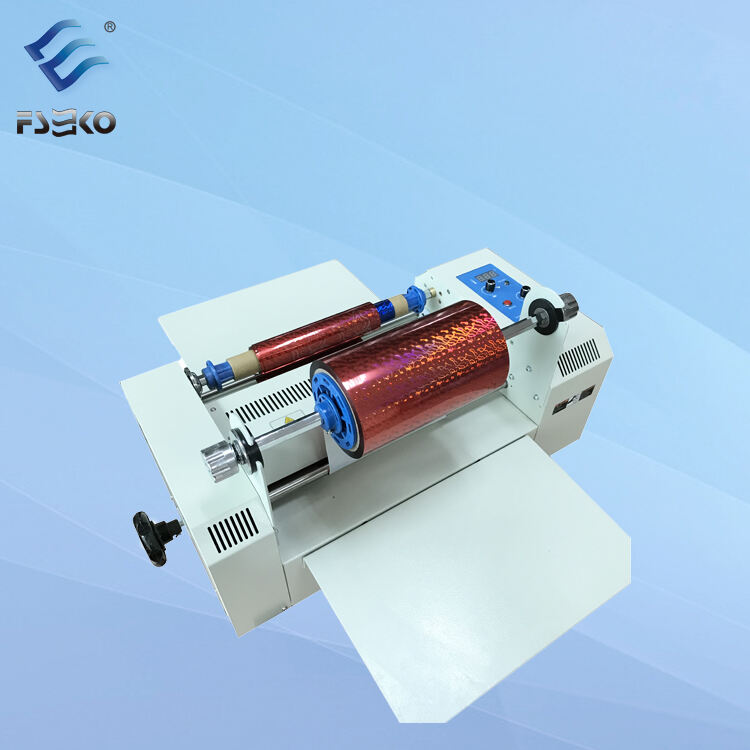

- User-Friendly and Versatile:

Ideal for transfer printing, ironing, various clothing transfer trademarks, transfer patterns, wash labels, personalized DTF printing, and more. It is suitable for DTF film printing on various textiles, including ready-to-wear T-shirts, cut pieces, shirt fabrics.

- High-Quality Print:

DTF printing produces vivid, high-quality prints with excellent color reproduction.

End-To-End Customer Support:

Customized Film Solutions:

Solve Your Specific Pain Points

Edge warping of heat-intolerant printing materials after laminating

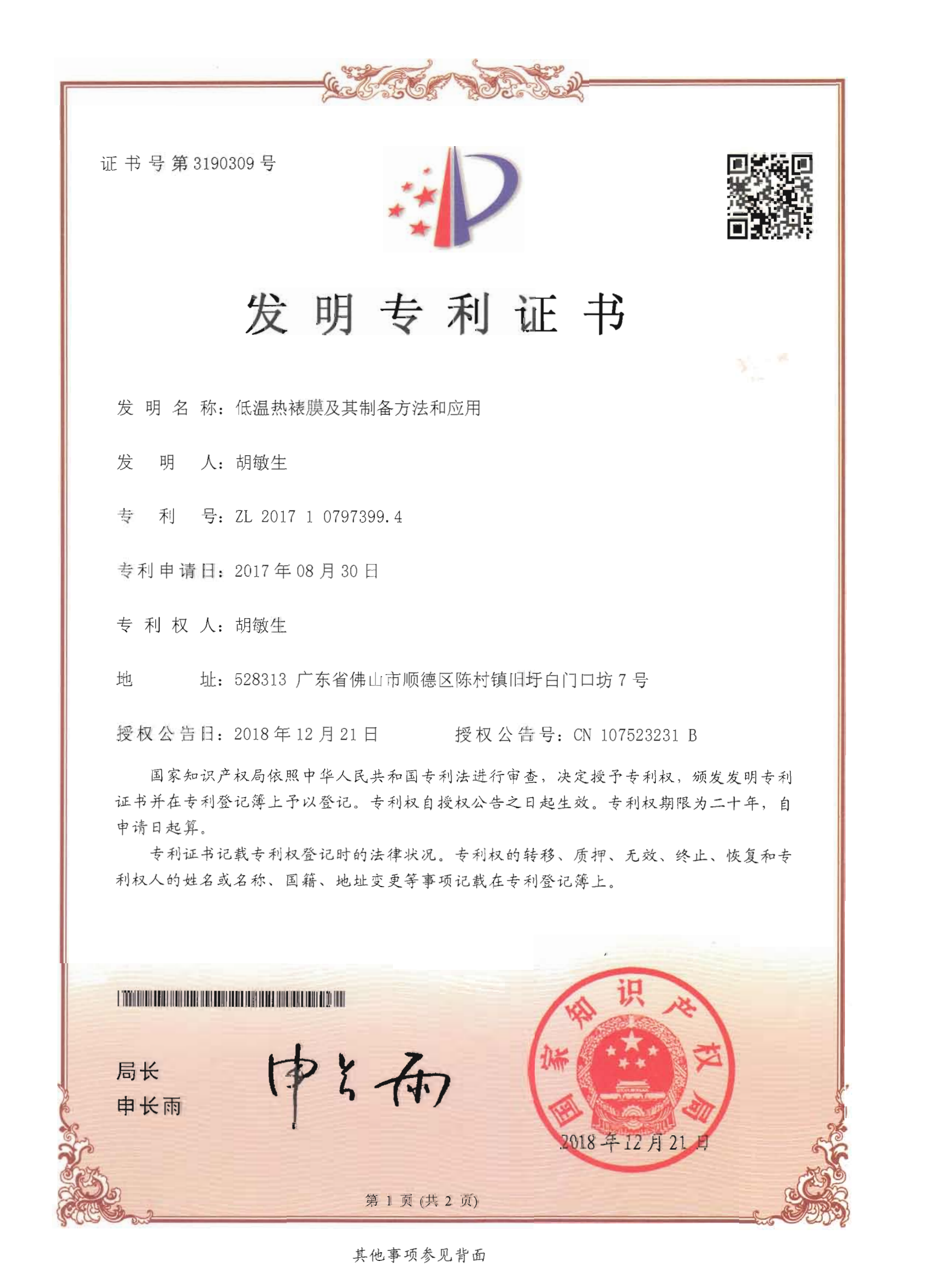

SOLUTION:LowTemperature Thermal Lamination Film

Delamination of digital toner printings after laminating

SOLUTION:Digital Thermal Lamination Film

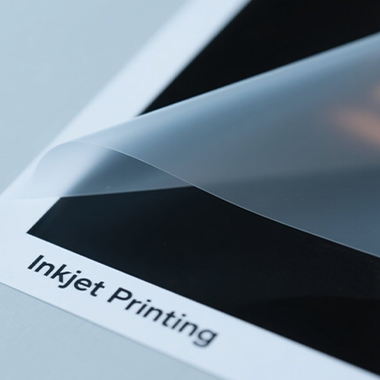

Low adhesive of inkjet printings after laminating

SOLUTION:Thermal Lamination Film for Inkjet Printing

Solution:

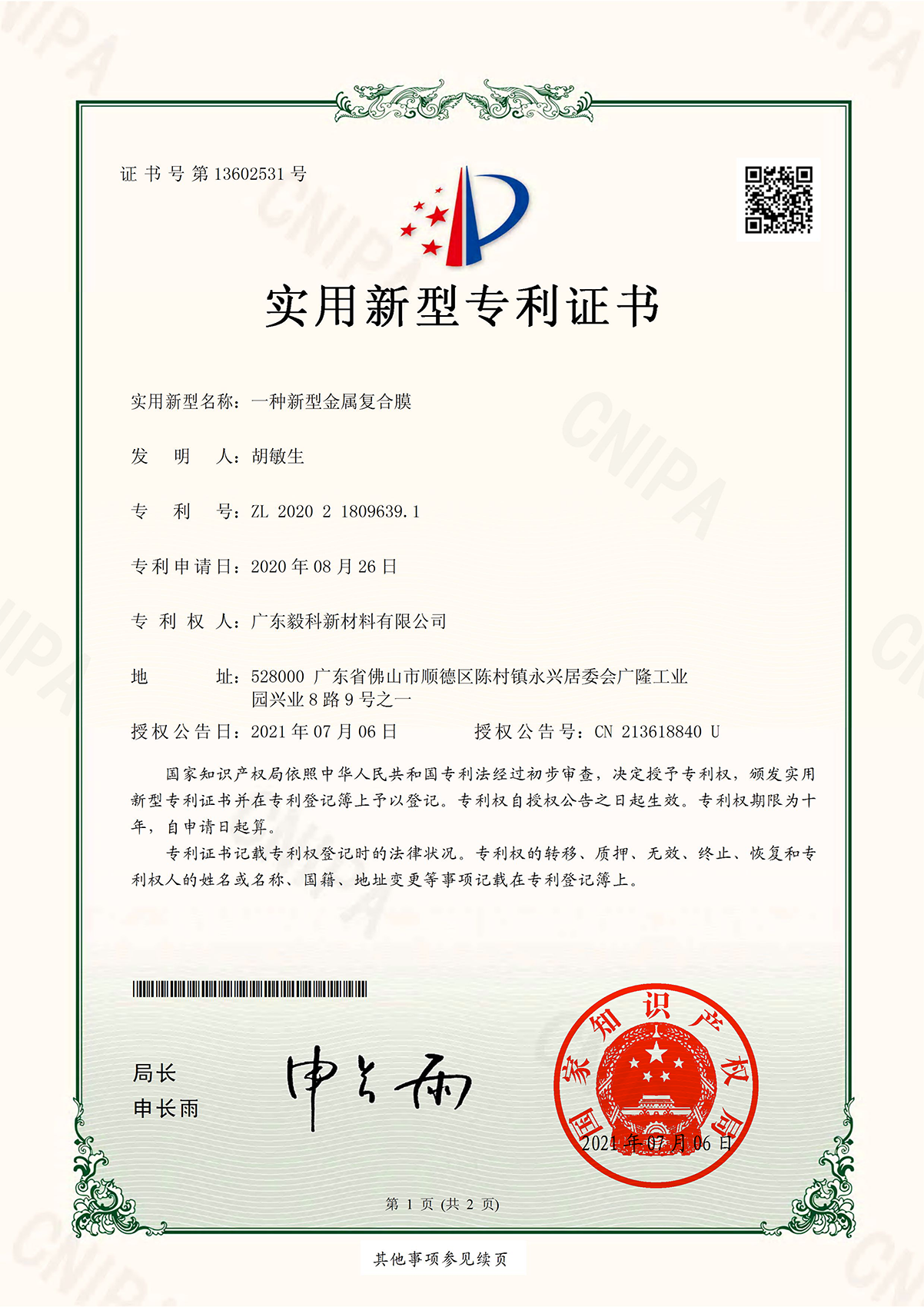

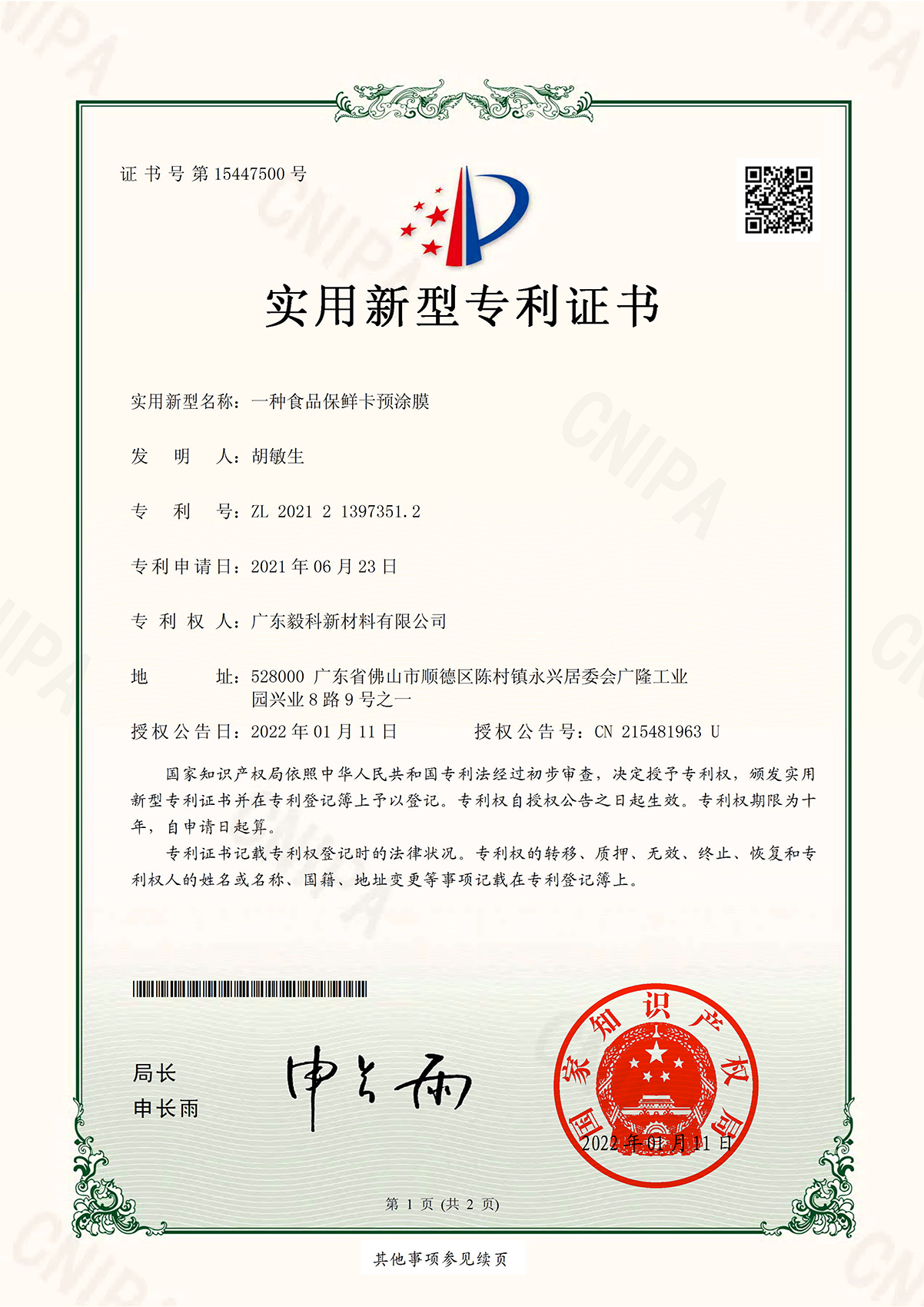

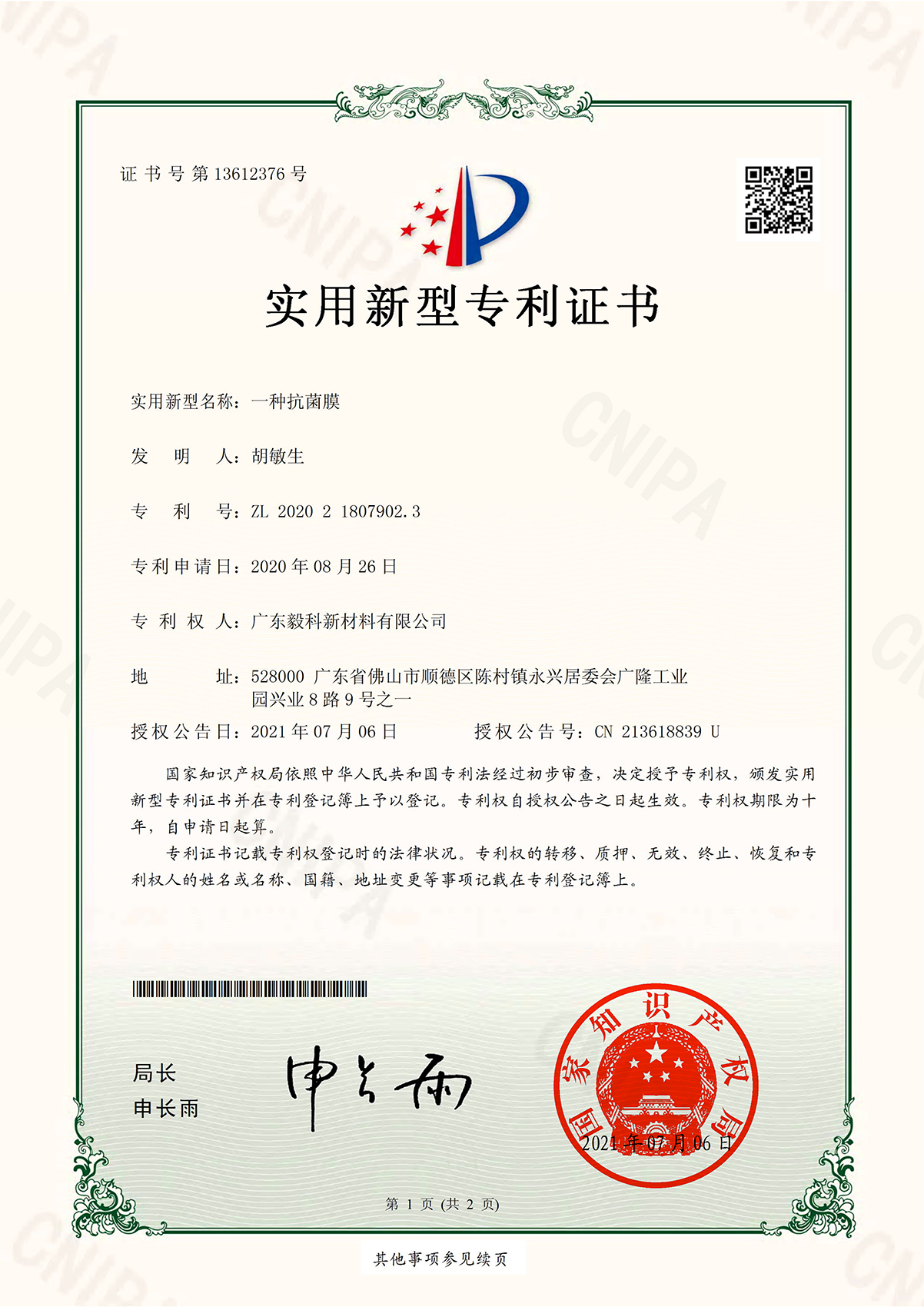

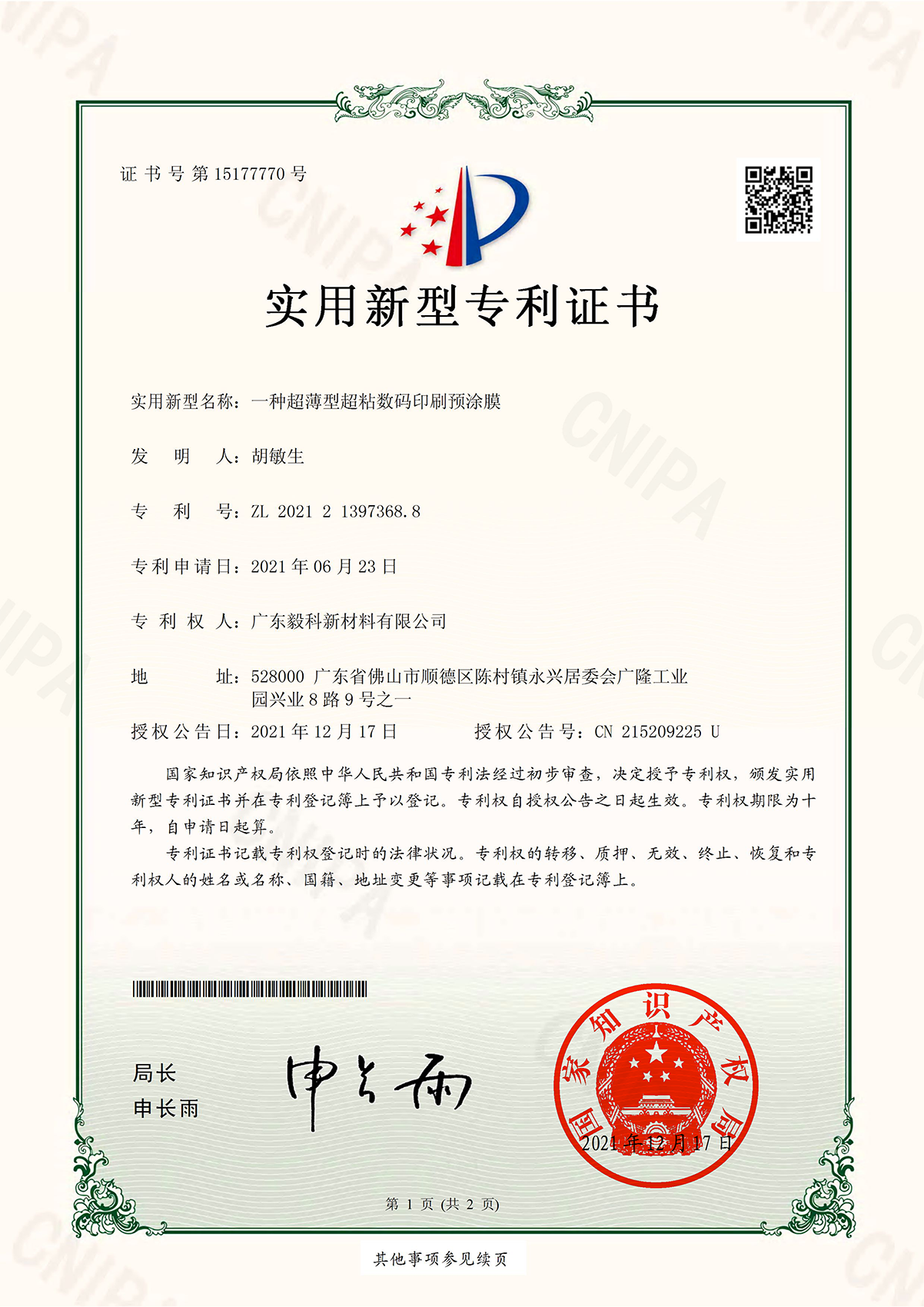

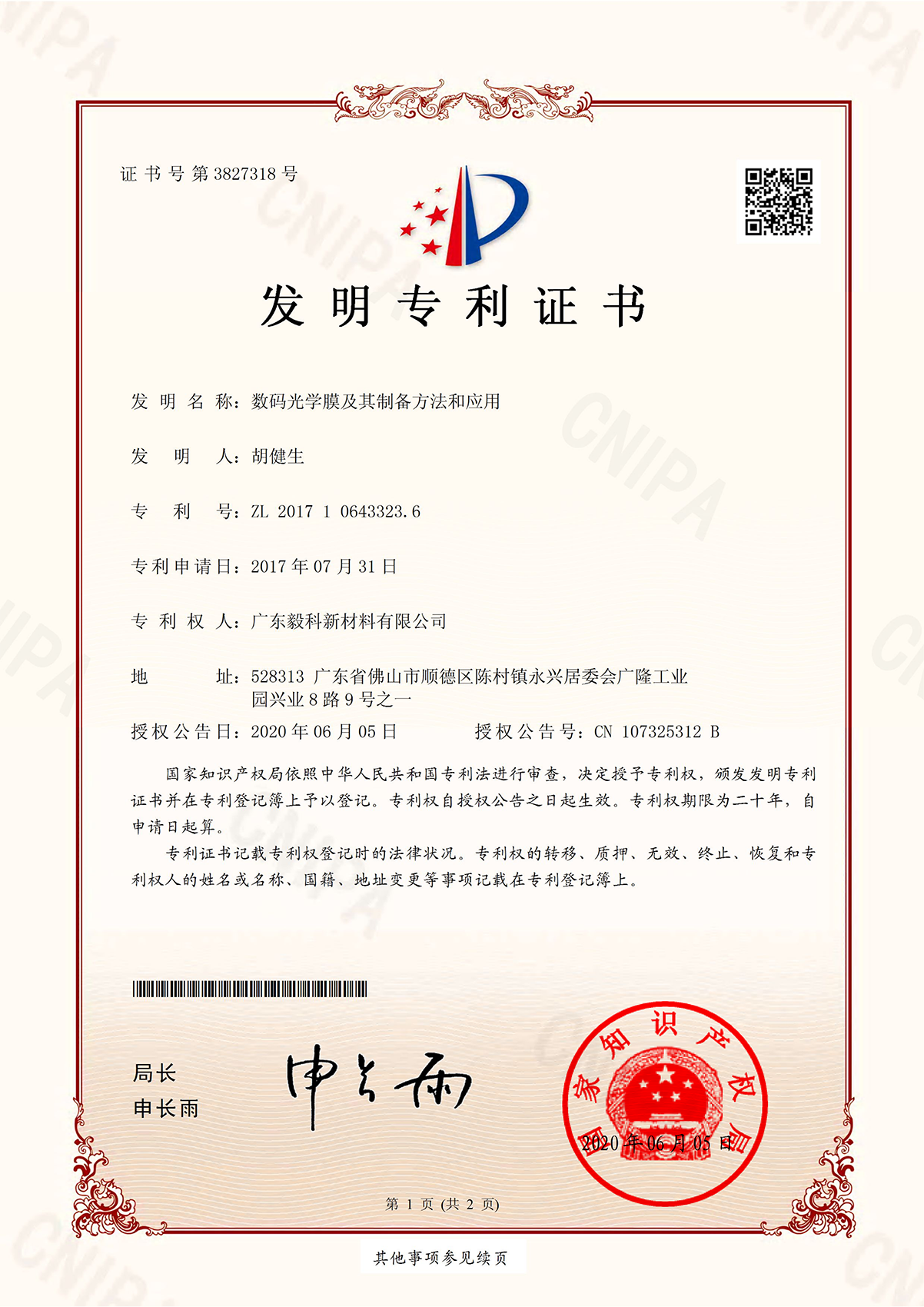

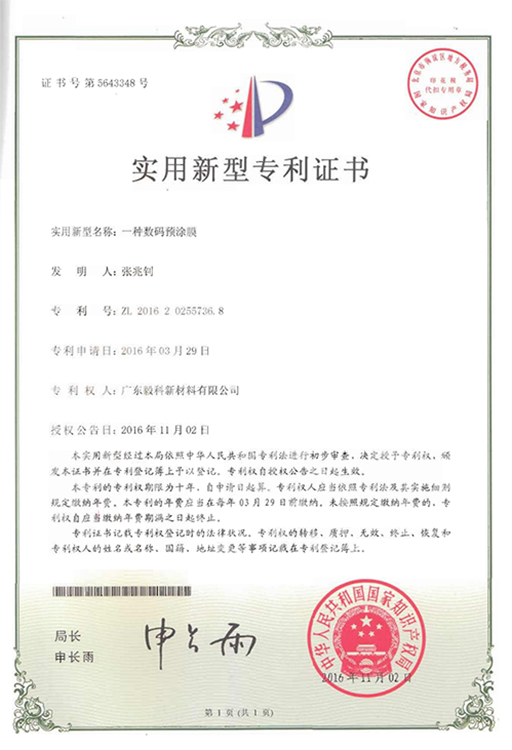

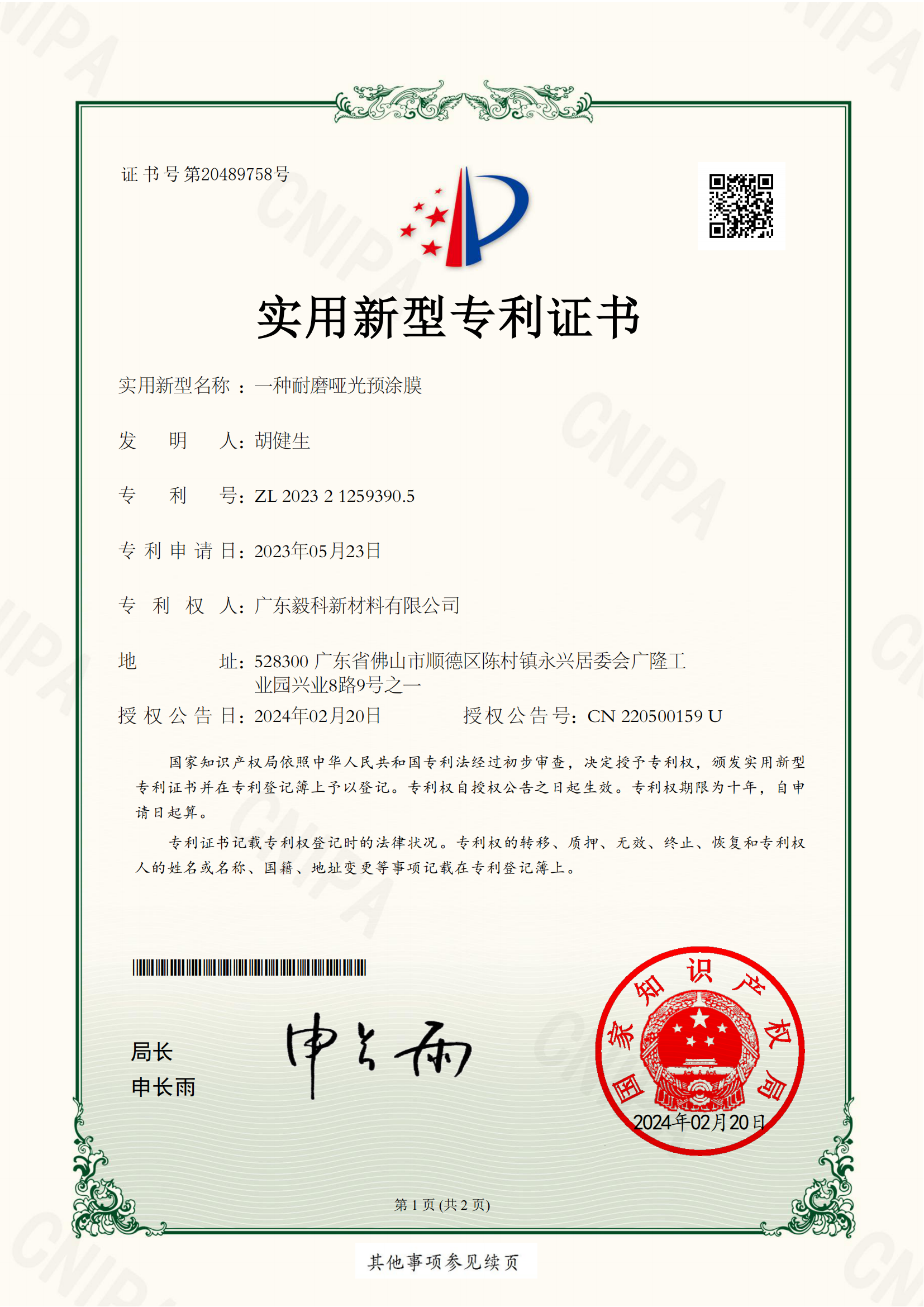

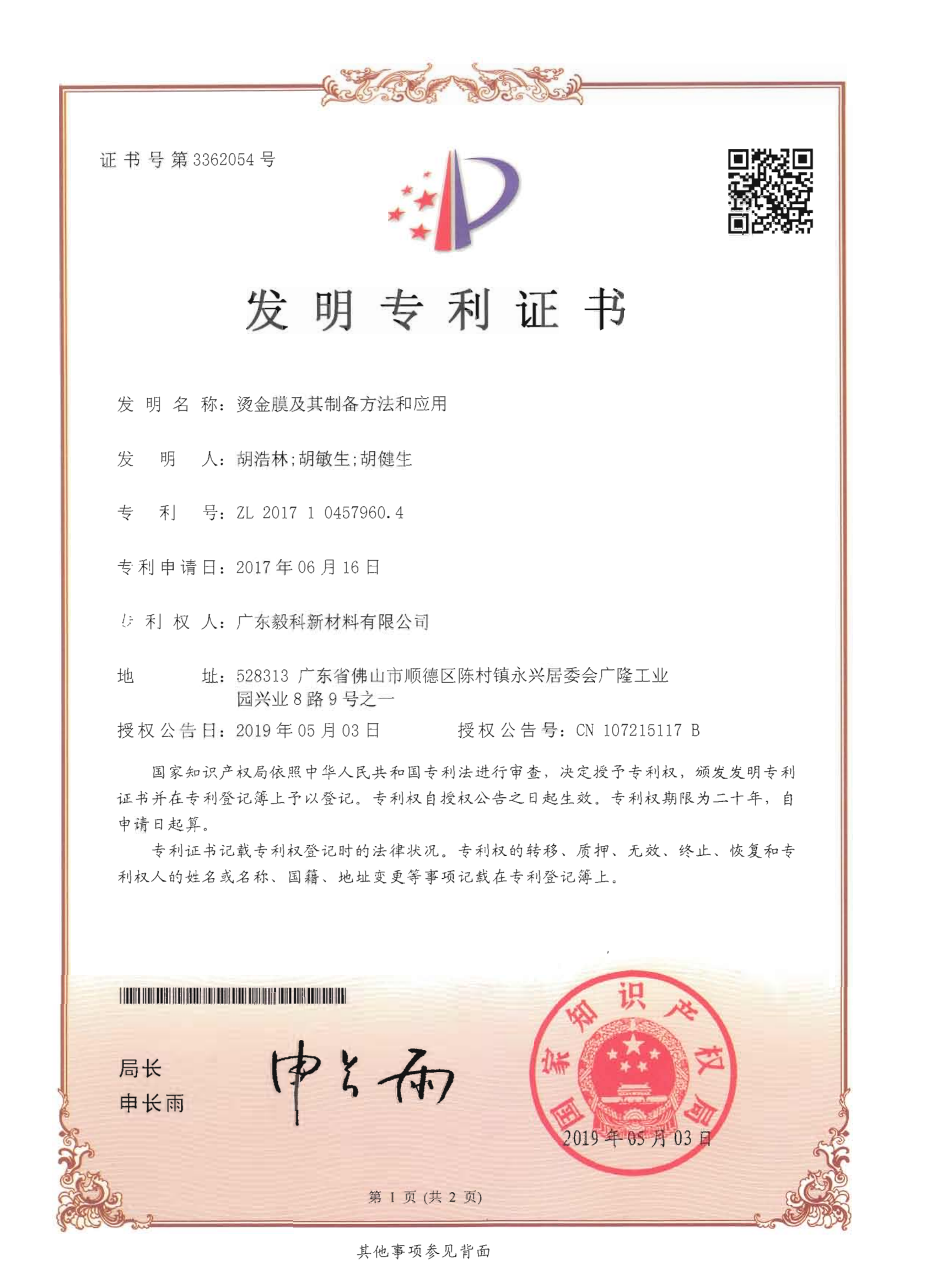

Deep Cooperation with School's Research Department Delivering Customized Solution

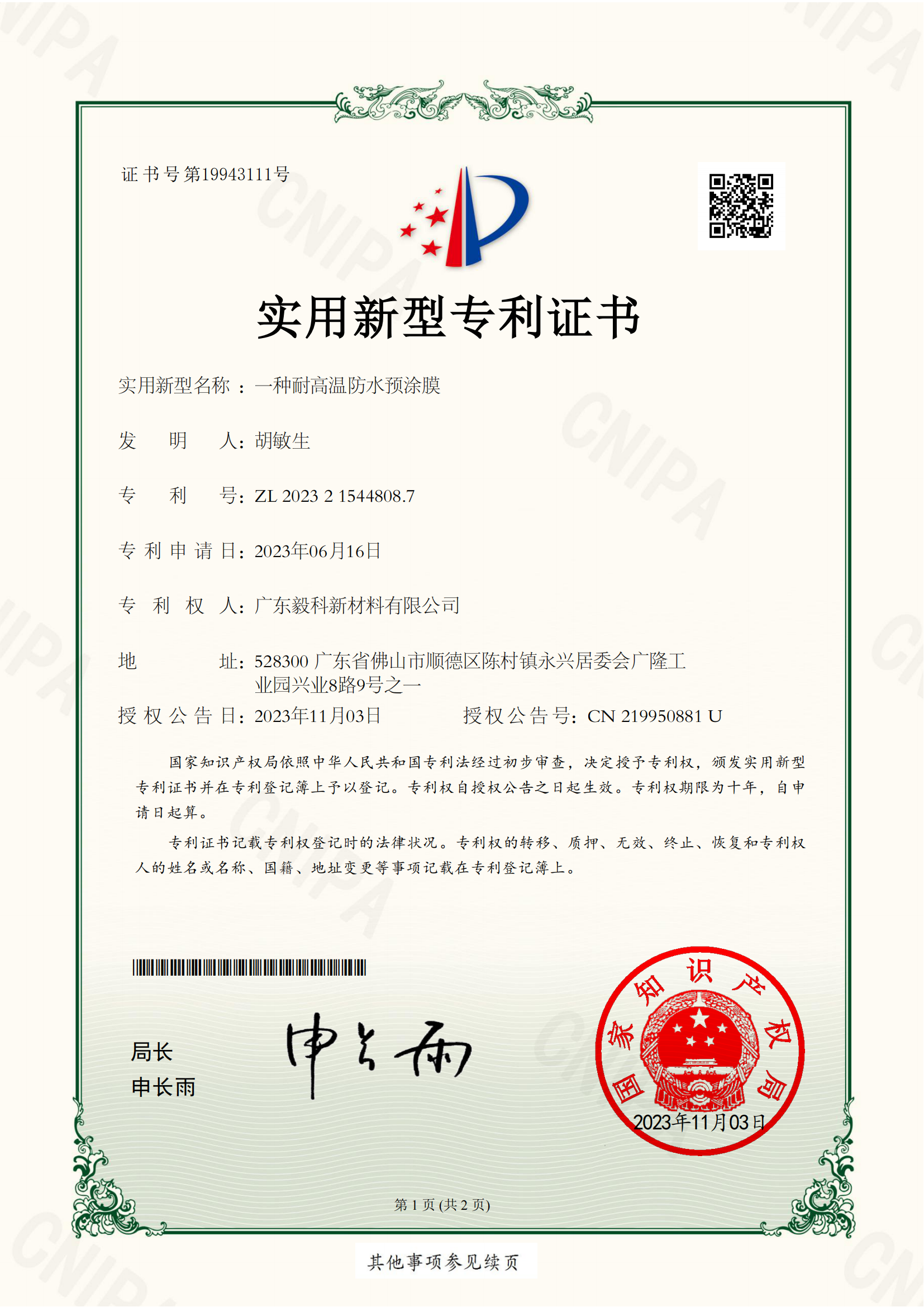

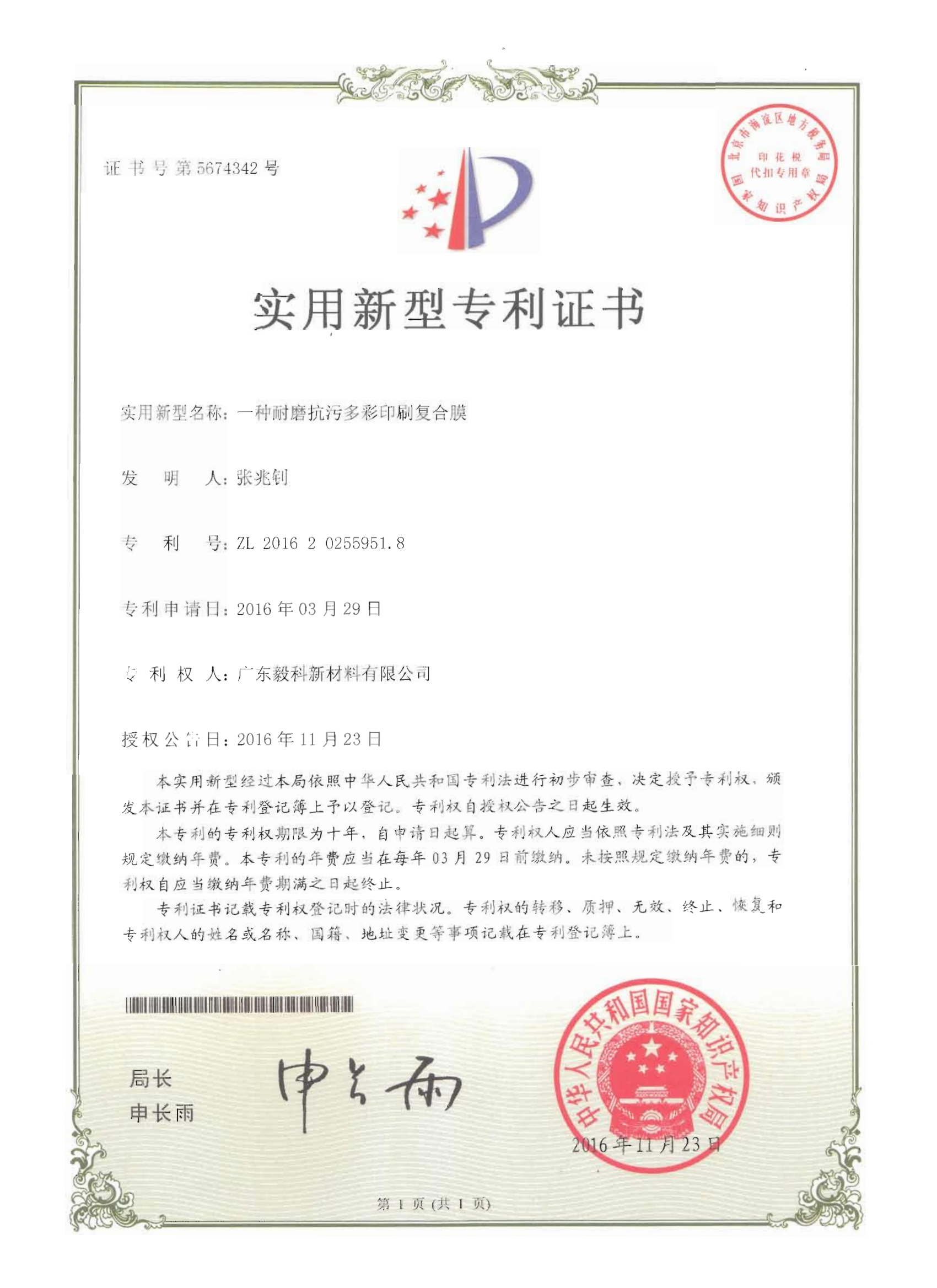

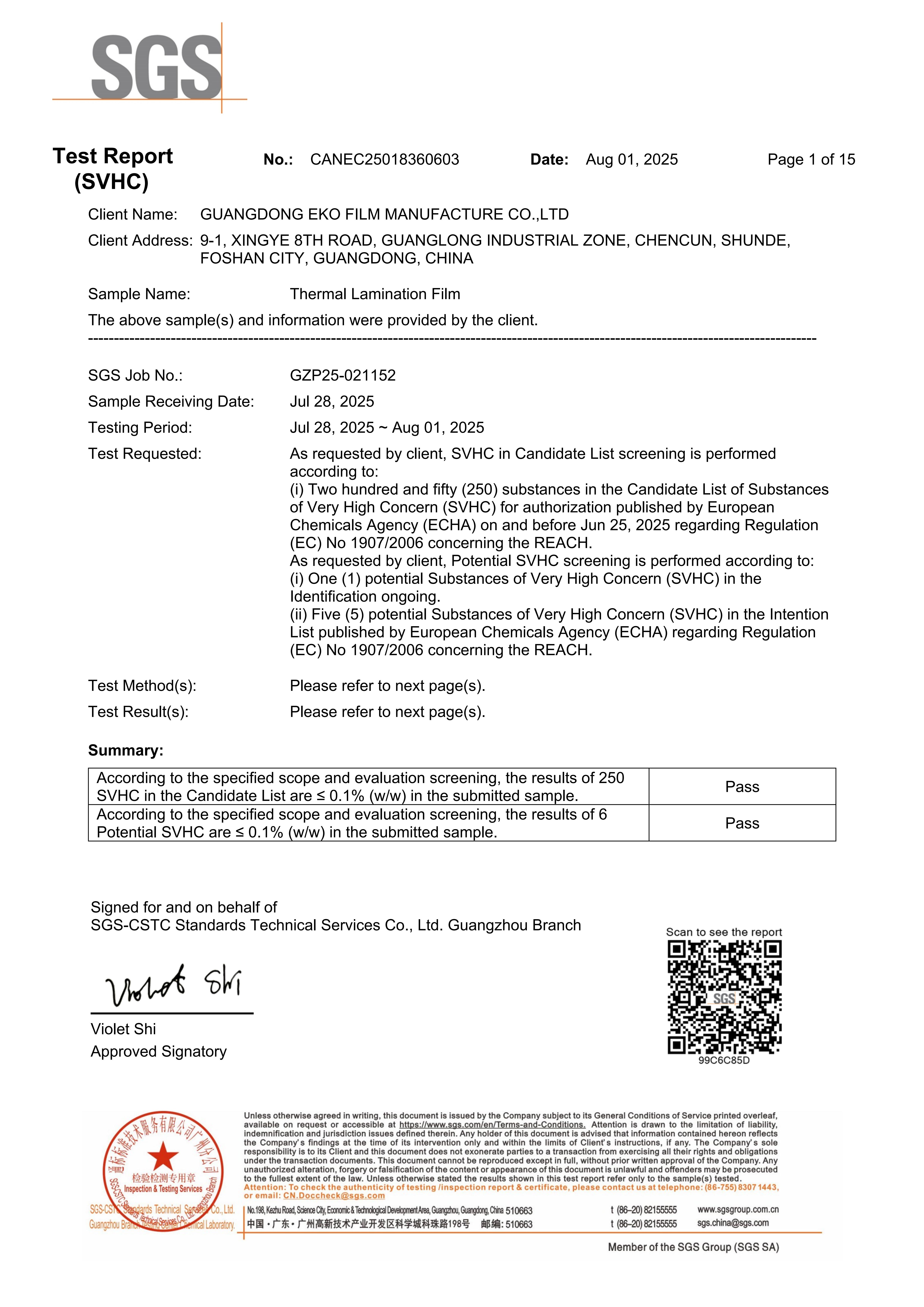

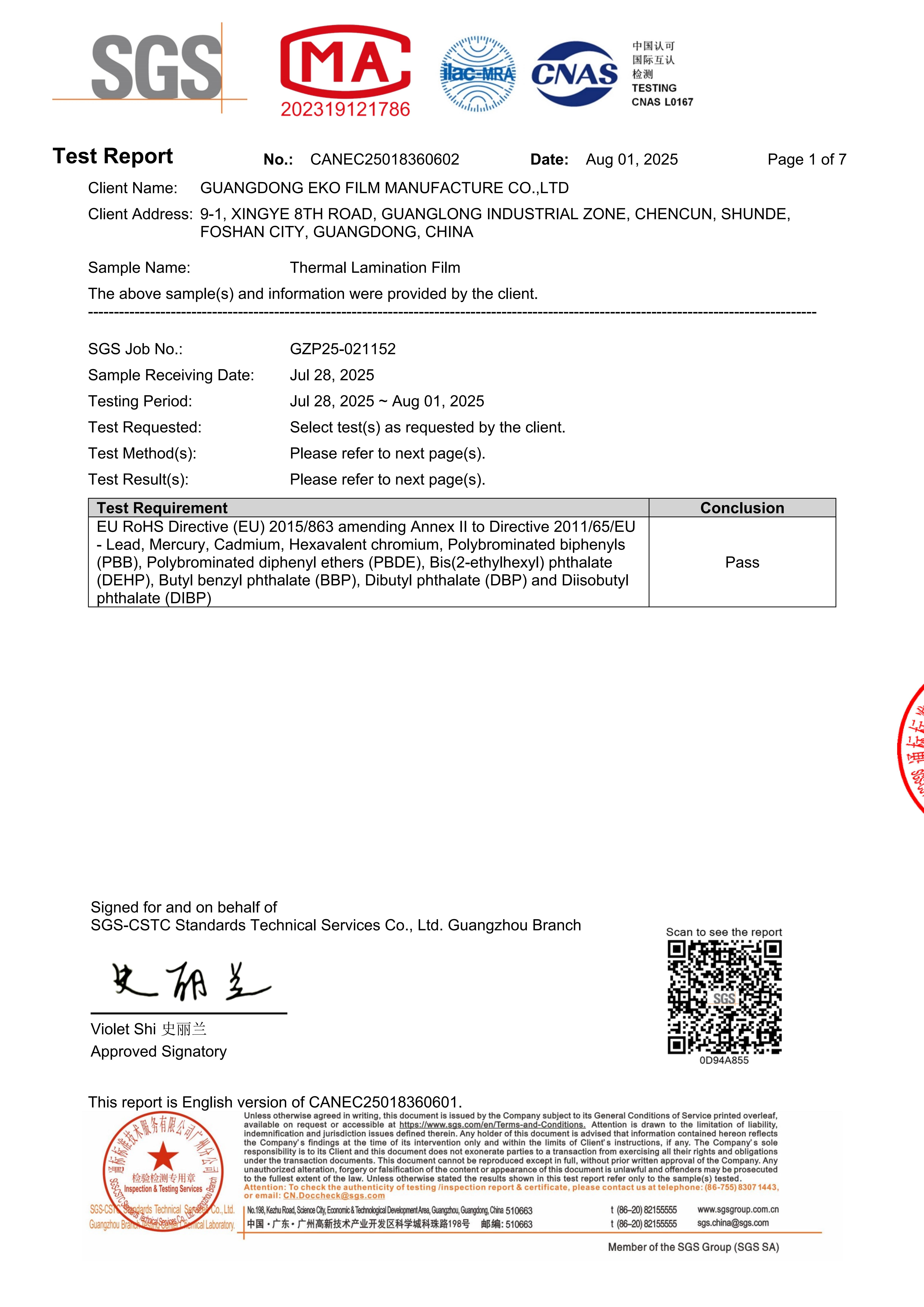

Compliance:

RoHS & REACH & Food Contact Material Triple-Certified

Packaging & Shipping:

FAQ:

Q1:Are you a factory or a trading company?

A: We are a company integrating R&D, production and sales.

Q2: How do you ensure the quality of your products?

A: We do end-to-end quality control-real time thickness check, corona value detection, bond strength testing, performance packaging.

Q3: What is your main products?

A: EKO has a broad product portfolio by catering to a wide range of industry needs, including BOPP thermal lamination film, digital super sticky thermal lamination film, thermal lamination film for inkjet printing, digital toner foil, DTF film & paper, heat sealable film, etc..

Q4: Can I get some samples or trial order for trying?

A: Yes, we provide free samples, the sample size is 320mm*30m per roll. You only need to pay for the shipping cost.

Q5: What services can we get?

A: We provide end-to-end customer support including professional customer service, customized solution, free samples, trial order, product information pack, technical consulting, full logistics tracking and feedback, comprehensive customer complaint process.

Q6: What payment terms do you offer?

A: We offer EXW, FOB, CIF, DAP, DDP, etc..